It’s a problem custom builders face more and more often. You’re building a high-performance home with advanced airtightness and insulation details. But your clients also want a trophy kitchen with a commercial gas range and a commercial-grade exhaust hood. The hood they’ve chosen can pull 800 or 1,000 cfm from the space. But in an airtight house, where does that air come from?

The building code has evolved to take this problem into account. The 2015 International Residential Code (IRC), Chapter 15 (Exhaust Systems), reads, “Exhaust hood systems capable of exhausting in excess of 400 cubic feet of air per minute … shall be mechanically or naturally provided with makeup air at a rate approximately equal to the exhaust air rate. Such makeup air systems shall be equipped with not less than one damper. Each damper shall be a gravity damper or an electrically operated damper that automatically opens when the exhaust system operates. Dampers shall be accessible for inspection, service, repair and replacement without removing permanent construction or any other ducts not connected to the damper being inspected, serviced, repaired, or replaced.”

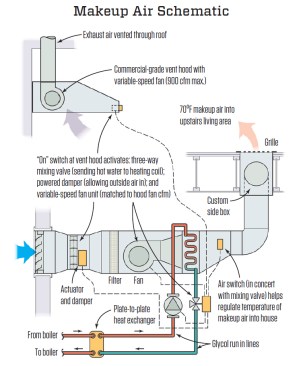

A makeup-air duct dumps into the living space.

Makeup-air requirements for range hoods are new in the code, and not every municipality has caught up. But whether makeup-air rules are enforced or not where you work, it’s well worth your while to consider the implications of a high-powered range hood. In conventional homes, range hoods can backdraft fireplaces and combustion equipment. In an advanced house, a range hood’s power can easily cause reverse air flows on a bath fan or overwhelm an energy recovery ventilator (ERV). Reversing a bath fan can lead to comfort and moisture problems in the bath, and interfering with an ERV can cause moisture problems throughout the house.

The issue came up this year on a large custom home under construction by Vermont builder Hayward Design Build on the shores of Lake Champlain. The home’s blower-door test came in at about 0.7 ACH50, says Jim Bradley, Hayward’s manager for building-science issues. “So we’re down near Passive House levels of airtightness.”

Tim Healey

Controls open the intake damper, adjust the fan speed, and activate the heating coil as needed.

Here’s the wrinkle, says Bradley: “This house is getting a gourmet-quality kitchen. This cooktop is going to have 168,000 Btu worth of burners, restaurant quality, with a restaurant-quality vent hood. We’re looking at a 600-cubic-foot-per-minute (cfm) outflow, on a house that’s going to be super-tight.” That 600 cfm of exhaust is “guaranteed,” says Bradley: The unit can sense airflow and ramp up to as much as 900 cfm at the intake point in order to achieve an effective outflow of 600 cfm.

Knowing how tight the house was going to be, Bradley was concerned. Fresh air for the house was to be supplied by four pairs of Lunos e2 ERV fans, plus one Lunos Ego unit in the bath. Lunos units alternate between drawing in air and expelling air, with an energy storage core serving to recover heat. But the kitchen fan could easily have overcome the small, low-voltage fans on the Lunos systems, causing them all to admit outdoor air at the same time and disrupting their heat-recovery functioning. “This could have been a building-science nightmare,” Bradley says.

Controls are wired to match intake fan speeds with the kitchen exhaust.

Under the floor, a fan draws outdoor air into a duct and passes it over a heating coil before directing it up into the home’s living space.

Bradley turned to Paul Blanchard at wholesaler F.W. Webb’s branch office in Williston, Vt., for guidance (fwwebb.com). The photos (above) show the system that Blanchard cooked up, as installed by Benoure Plumbing, Heating & Air Conditioning of South Burlington, Vt. (benoure.com). Complicating the problem was the fact that this house, built on a superinsulated slab, has no real basement aside from a small 12-foot-by-12-foot under-floor area for mechanicals. It was into this mechanical space that Bradley and Blanchard had to squeeze their makeup-air duct system.

A dampered louver at the exterior wall is controlled by a relay that’s wired into the switch for the kitchen range hood. Also wired to the kitchen switching is a control for the intake fan. Bradley says, “We were able to tie into the low-voltage control at the hood, and we ran wires all the way back to the basement so that when the cook selects low, medium, or high, it will cause the combustion air makeup fan to ramp up accordingly. It’s designed to marry what is going on at the vent hood.”

Vermont has cold winters, and dumping 600 cfm of fresh air into a heated room in the dead of winter could cause some discomfort. For that reason, Blanchard provided for heating the makeup air by placing a hydronic heating coil in the duct run between the outdoor intake and the floor grille where makeup air emerges into the upstairs living area. The heating coil is equipped with a thermostat and control circuitry that senses the indoor temperature and the temperature of the indrawn outdoor air, and it warms up to temper the incoming air as needed.

Photos by Tim Healey