- Q. What’s the best nailing pattern for built-up beams?

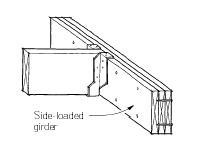

A. The critical issue with built-up beams is that all the layers must deflect together and by the same distance in order to be properly sharing the load. For beams where the load comes down evenly on top of the beam, such as drop beams or beams directly under bearing walls, the nailing pattern is not all that critical. All you need are enough nails to hold the layers together and keep them from twisting. For beams loaded from the side, however, and especially for beams loaded from one side only, the nailing pattern is critical.

When beams are loaded from the side, there must be enough nails to transfer the load through the loaded member and into the attached members. For example, if a beam consists of three 2x10s loaded from one side only, the loaded member should only carry 1/3 of the weight. To transfer the rest of the load into the attached members there must be enough nails from the loaded 2×10 into the center 2×10 to transfer 2/3 of the load, and enough nails from the far side 2×10 into the center 2×10 to transfer the final 1/3 of the load into that outer member. These numbers assume that all three 2x10s rest fully on the supports; the situation gets more complicated when the members are not all the same size or material. The bottom line, though, is that if all the pieces deflect together and equally, the beam should perform as designed.

At a minimum, I recommend pairs of 16d nails every 12 inches along the beam, with the top row of nails 1 1/2 inches or so from the top of the beam, and the bottom row 1 1/2 inches or so up from the bottom. Use the same nailing pattern on both sides for triple beams, and check with an engineer whenever you think the loads involved might be unusually heavy.

—C.D.

Nailing Patterns for Built-Up Beams

"Four engineers shed light on common framing mysteries, myths & misconceptions"

2 MIN READ