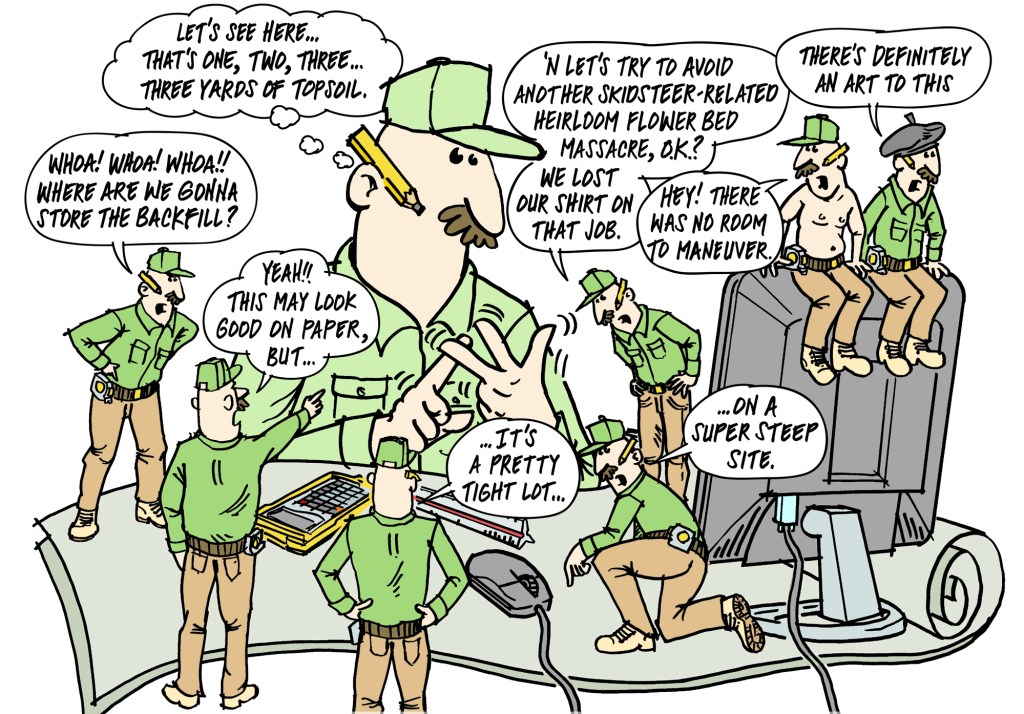

It’s been said that estimating is more of an “art” than a “science,” and I tend to agree. The “science” side of estimating is the quantity takeoff—counting the number of doors on the plan, measuring the linear footage of baseboard or the area of hardwood floor, or calculating the volume of concrete in the footings. The “art” side takes more thought and requires the person putting the estimate together to consider all the factors that will affect productivity, which will ultimately affect the cost of the work. I can quickly teach anyone how to do a quantity takeoff—I’ve even had my 12-year-old daughter help me with counting doors or light fixtures, and she has done a great job. The “art” part, though, takes more time to learn and usually comes only with experience. The goal of this article is to shorten the learning curve on the “art” side by highlighting some of the things you need to consider when you’re putting a price together.

Site Access and Logistics

Let’s say you have two clients, both of whom want you to build a 12-foot-by-40-foot addition on the back of an existing house, with an extension of the basement below the addition. The first house sits in the middle of a flat, 2-acre piece of property, with at least 50 feet of clear space on each side, 100 feet behind the house, and easy access from the road up the driveway to the backyard. The other house is in a neighborhood of 100-year-old houses, with 10 feet between houses, 30 feet to the back property line, dense landscaping all over the property, and a road in front of the house that’s barely wide enough for two cars to pass each other.

The additions that are planned for these two houses are exactly the same, but will the prices for the projects be the same? Well, it’s likely that the volume of dirt you need to excavate for the basement can be calculated easily enough, and it’s probably about the same amount for both additions. The amounts of concrete block, framing lumber, roofing, and other materials will be similar as well—but that’s where the similarities will end.

For the first house, you’ve got plenty of room to get whatever equipment you need into the backyard for digging the basement, as well as to get dump trucks in to haul off soil. You’ve also got room to stockpile soil for backfilling the foundation; bring in trucks delivering lumber, drywall, roofing, and other materials; and set up your saws and other tools while you’re on the job.

The second house does not allow for any of this, however, so the cost to build its addition will be higher. For instance, you’re going to have to remove existing landscaping to gain access to the backyard, and you’ll have to either include money in your bid to replace it, or exclude the replacement of landscaping in your bid. In the latter case, the homeowner will have to pay for that work separately. How you choose to handle that will depend on your clients and your business model: If your clients expect a turn-key project and don’t want to deal with paying a landscaper to repair the yard, you’d be better off including the restoration cost in your pricing.

Since you may have only 5 feet between the house and the property line, you’ll have to excavate the basement with a smaller machine, or get permission from the neighbor to cross the property line with your excavator and trucks. In that case, you can be pretty sure that you’ll be paying to restore the landscaping on the neighbor’s side of the property line, so you’d better include that cost in your bid.

Let’s assume the neighbor won’t allow you on his property. You’re now stuck with that small excavator and no way to get trucks into the backyard to get the dirt out, so not only are you digging with a smaller machine that takes longer (and costs more), you’ve also got to take all the excavated dirt to trucks that are parked in the street, which adds even more time and cost and makes a mess at the street that will require daily cleanup. Wait, there’s more. You’ll also have limited room in the backyard for material to backfill the foundation with, so you’ll be hauling that material away, and then paying to bring material back (and moving it to the backyard to backfill with).

All of this must be factored into the cost of the project (and the schedule will have to be adjusted, as well). And bear in mind these complications will carry through the entire rest of the project: You’ll have to pump concrete from the street, hand-carry all of your material to the backyard from the street, and time deliveries precisely since there won’t be much room to have material arrive early and be stored on the site.

Room Dimensions and Shape

While they may not have as dramatic an impact as the site-access issues discussed above, room dimensions and shape can affect the cost of a project as well. As an example, consider two rooms that have the same perimeter, but one is a simple rectangle with four inside corners and the other has several bump-outs and includes seven inside corners and three outside corners. If you’re installing baseboard in the simple rectangular room, you have to cut and handle four pieces and fit four corners. If you’re installing the same trim in the other room, you have to cut and handle 10 pieces and fit a total of 10 corners. The labor cost (time) of installing baseboard, crown, chair rail, or wainscot isn’t affected much by the length of the pieces. The time is all in cutting the pieces and coping and fitting the corners, so the more complex room can easily take twice as long to trim as the simple rectangular room.

When putting an estimate together, you start, of course, by measuring the total linear footage to determine the material cost. But the more critical part of the overall cost will be the labor, which you need to determine based on the number of corners you’re going to have to fit. Depending on the size of the base or crown, the type of material, and how square and level the room is, each corner could take anywhere from 15 to 30 minutes (or more) to fit. When you have 10 corners, that can add quite a bit of time to your day and quite a bit of cost to the project.

Here again, actual room dimensions play a role, and when paired with standard sizes of material, they can seriously mess with costs. For example, if the longest length of crown molding you can get is 16 feet, and you’re putting crown in an 18-foot-by-18-foot room, you’ll have four joints to deal with, since the walls are longer than the pieces of material you can get. If you just do a quick linear-foot takeoff around the room and don’t consider this, you might charge enough for the material itself, but you won’t have factored in enough time and labor cost to cut and fit scarf joints on all the walls.

The available length not only affects labor cost, but it can affect material costs, as well. For example, if you’re trimming a small, 9-foot-by-9-foot bedroom, and you can get crown molding only in 12-foot lengths, you’ll be cutting off 3 feet from each stick, basically “wasting” 25% of your material. This may not be a big deal when you’re installing 3 ⁵/₈-inch primed MDF crown that costs less than $1 per foot (although $12 is still $12 and should be accounted for in your estimate), but it is when you’re installing custom-milled 6-inch cherry crown that costs $8 per foot. Now, if you were installing crown throughout the house, you’d probably have some short walls somewhere that you could use the cutoffs on, but if it’s a one-room job, you must consider this, as it can quickly eat into your profits.

Location within the House

You need to consider where in the home you’re working, and also where you’ll be setting up your work area. Working in a ranch house with your saw set up right outside the front door will be far easier than working on the third floor of an old Victorian home with narrow, winding staircases and having your tools and equipment down on the first floor. Not only will you have to factor in the time to travel up and down two flights of stairs for every cut, every forgotten tool, and every piece of material, but you’ll also likely get tired from all the up and down as the day goes on, which will further reduce your productivity. While I’ve picked an extreme comparison, it’s not outside of the realm of possibility when you deal with clients with widely divergent demands for where you can set up.

You’ll also need to develop a plan for getting material to the work area. Finishing the attic of a house may require you to remove a window to have drywall boomed in. That removed window could also come in handy for other large items, like a one-piece tub enclosure, or heavy items, like large quantities of tile. You’ll have to include money in your price to cover the removal and reinstallation of the window, as well as any special handling costs for boom trucks, cranes, or lifts, but in the end, this will probably cost less than carrying all of that stuff up through the house (if that would even be possible).

Age and Condition of the House

Working in older homes often takes more time and effort than working in newer homes, since over time walls and floors have settled, resulting in out-of-square corners and floors that are out of level. Making, or adjusting, new doors, cabinets, and trim to fit and work correctly in older homes can take considerable time, since you often need to trim and scribe new materials to work with the old materials you’re tying into.

It’s of paramount importance when visiting an older house for the initial estimate to bring a level and a square with you so you can determine how bad things are. Be sure to factor in adequate time for all the trimming, tweaking, and adjusting that will be required, and for any conditions that you think will be difficult or impossible to make “right.” Hanging cabinets on a wall that’s an inch out of plumb, for instance, will require a lot of shims and scribe molding, or you’ll end up with doors that don’t stay closed without catches. Be sure to bring these items to the client’s attention in writing prior to starting the work, and be sure to have the client sign off on them.

Another thing to consider when working in older homes is your ability to match existing finishes. If the existing house is all plaster on wood lath, how will you be making repairs and patches in the areas you’re working in? If you’re planning to use drywall and joint compound, will you be able to match the texture of the existing walls and ceilings? If not, include a clarification in your proposal stating that there may be differences in the finish, so your customers understand what the finished product will look like.

The same applies to matching trim profiles, flooring materials, stain colors, and other existing finishes. If you’re extending an existing wood floor into an addition, will you be able to match the flooring material? If you can match the material, will you be able to get away with just toothing in the wood and blending the stain and finish into the existing floor, or will you need to sand and refinish the entire first floor to get it all to match? If you’re adding crown molding in the addition, will you be able to match the profile with off-the-shelf materials, or will you need to get a custom knife ground and have the new crown milled to match the existing?

Be very careful with using the term “match existing” in your proposal unless you’re truly able to “match” the existing materials and have included the cost of doing so in your proposal.

Occupied Or Vacant

Finally, you need to consider whether you’ll be working in an occupied space or in a vacant space. If the majority of your work has been in new homes that have not been moved into yet, and you’re now pricing a significant renovation in an occupied house, you’ll be in for a rude awakening if you don’t price the work accordingly. You need to include the cost of installing temporary walls for dust protection, fans to draw dust out while you’re doing demolition work, and protection for the existing floors and walls in the areas you’ll be walking through to access the area you’re renovating. You may need to install a temporary toilet if you’re renovating the only bathroom in the house, install a temporary kitchen sink for your clients to use while you renovate their kitchen, or provide temporary air conditioning while you replace an HVAC system. You also have to be much neater when working in an occupied home—you can’t leave trash, boards with nails sticking out, or tools laying around at the end of the day, and time needs to be allotted to every day for cleanup.

Bottom Line

While it would be impossible to cover everything you may encounter in the process of pricing a project, hopefully you have a better understanding of the big-picture items and a new appreciation for what goes into preparing an accurate estimate. The issues discussed here can make the difference between a successful project and one that ends up either robbing you of whatever profit you would have had at the end of the day, or (far worse) costing you money to complete.