In the recent PDB article Durable Deck Details, Minnesota builder Brian Jacobson notes that while he uses HDG joist hangers, he likes to upgrade to stainless steel fasteners. He’s worried about a galvanic reaction between the hardware and the copper in PT lumber, and thinks that SS fasteners embedded in PT lumber will last longer than HDG fasteners (to minimize contact between his fasteners and his lumber, he also wraps the ends of his joists with a membrane prior to installing hangers).

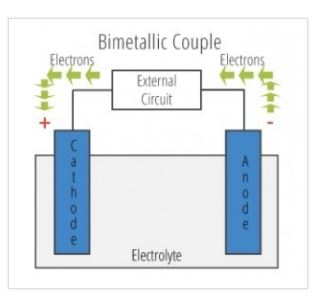

Prior to publishing the article, I had questioned Jacobson about this detail, reminding him that galvanic reaction is always a concern when dissimilar metals come in contact with each other. While acknowledging that there was a risk, he explained that the additional cost for SS vs. HDG fasteners was relatively small compared with the cost of upgrading to SS hangers (a tough sell to most of his clients). He told me he had done some research on the topic and pointed me toward the American Galvanizers Association website, where several articles explore what happens when zinc comes in contact with other metals. Based on his reading, he said that he would be much more concerned about galvanic corrosion if he was using SS hangers and HDG nails (where the hangers act as the cathode – or protected – side of the electrochemical reaction, and the fasteners act as the anode and are sacrificial), or if he lived in a saltier environment. He also pointed out that he had been monitoring projects where he had used galvanized hangers and SS fasteners, and hadn’t observed any corrosion.

Wormer, Andrew

Because deck hardware manufacturers specifically recommend against mixing dissimilar metals, I then reached out to Bob Leichti, who is the engineering manager for Simpson Strong-Tie’s Fastening Systems division. While Leichti credited the builder for trying to come up with a more durable framing detail that is also cost-effective, he also reiterated the fact that Simpson recommends using fasteners that are coated to match the connector. In an email he goes on to write:

“In the case where the fastener is 300-series SS and the connector is zinc galvanized, the galvanic response will be that the connector zinc will be the corrosion victim. Ultimately, the SS nail will be left in contact with bare steel. The bare steel and the SS are not galvanically as different as the zinc and the SS. However, once the zinc is lost, the bare steel is open to regular oxidation type of corrosion as well as the marginal galvanic effect. The builder is correct that the SS nail is the cathodic side and the much bigger connector (zinc plus steel) is always the anodic side of the galvanic reaction, and this relationship will keep the corrosion on the connector rather than the smaller SS nail. This may also be a case where the size of the connector relative to the nail works in favor of the connector. The performance of this arrangement will also be affected by the amount of moisture present. If the connectors are well-ventilated and dry, the galvanic action will be minimized.”

My takeaway? Despite the widespread shift towards ground-contact (AWPA UC4A) PT lumber, Jacobson is probably unduly worried about a galvanic reaction between the lumber and his hardware. As far as I can tell, no hardware manufacturer currently recommends the use of a barrier membrane between its connectors and PT lumber, regardless of the treatment or retention level. And he could probably save a little money by using HDG instead of SS fasteners.

Of greater concern is the environment. Most deck builders realize that stainless steel hardware is required in “severe” (that is, coastal) environments. But chlorides aren’t limited to the sea shore; corrosion is a real problem where salt is used to melt snow and ice off a deck. In some areas of the Midwest and Northeast, metal connectors used on a deck are essentially bathed in a salt brine solution for a good part of the year. In this situation, both the fasteners and hardware should probably be upgraded to stainless steel, despite the added cost. For the latest info from hardware manufacturers on corrosion, see a pair of recent technical bulletins from USP and from Simpson Strong-Tie.