I recently did a remodeling project that involved replacing a th…

I recently did a remodeling project that involved replacing a three-season sunroom with fully conditioned living space. Since the budget was tight, we kept the original sunroom’s footprint and built on the existing brick pony wall, which was uninsulated.

The owner had lived in the house for 30 years and assured us that the sunroom had been built on a proper foundation. In our part of southeastern Pennsylvania, the code requires a minimum footing depth of 36 inches. Prudence and the building inspector required that we dig down to the footing and confirm it was where it was supposed to be.

Unfortunately, the homeowner’s memory was not very accurate. The footing was barely 24 inches below grade. The inspector gave us two choices: We could tear out the existing foundation – and the pony wall itself – and start over by pouring new footings 36 inches deep, or we could underpin the existing foundation to the required depth. Either option would increase the cost of the project by at least $10,000, which was more than the homeowner was willing to spend.

Given the tough economy, I didn’t want to lose this project. Looking for a more cost-effective way forward, I went back to a JLC article about frost-protected shallow foundations, in which a footing placed above the level of the local frost line was protected from freezing with layers of rigid foam (see “Super-Insulated Slab Foundations,” 4/10). Since it was evident that the existing foundation didn’t need much additional protection from frost – it had already lasted three decades without heaving or cracking – this seemed like a good solution. I also read through the NAHB Research Center publication “Revised Builder’s Guide to Frost Protected Shallow Foundations,” which provided some useful detail about the science behind this technology. After some further research into the code, I came up with an approach I was confident would work.

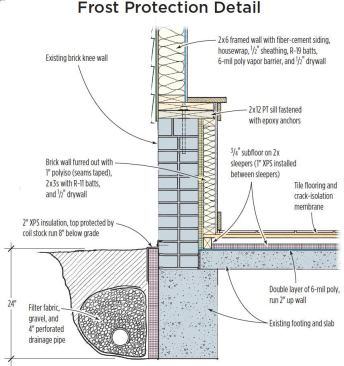

My plan called for excavating to the bottom of the existing footing and installing a continuous layer of rigid polystyrene insulation against the foundation wall, all the way down to the base of the footing. This insulating “curtain” would slow the passage of heat from beneath the slab into the soil beyond the footprint of the building, keeping the ground under the footing safely above freezing. Since wet soil conducts heat better than dry soil – and is more susceptible to heaving if it freezes – we also proposed installing a perimeter drain.

I emailed the building inspector copies of all the documentation I’d pulled together, including tables R403.3(1) and R403.3(2) from the 2009 IRC, which list our area as having an air freezing index of less than 1,000. According to the table, the footing depth of a heated building under those conditions can be as little as 12 inches below grade, provided that it’s insulated with an exterior layer of 1-inch polystyrene, with no requirement for extending the insulation horizontally. I also included a section drawing of our proposed plan – which, for an added margin of safety, called for a 2-inch layer of foam.

The inspector agreed to the plan, and actual construction went off almost without a hitch. We did have to do some fiddling to get the foam to lie neatly against the foundation in areas where the concrete was a bit rough, but this was a minor problem. We also lined the trench with filter fabric and installed a 4-inch drainpipe that ran to daylight, before backfilling with clean 1-inch stone. The upper edge of the foam finishes flush with the finish grade, where it’s capped with a strip of aluminum coil stock. The coil stock is caulked into a 1/2-inch slot ground into the mortar and fastened with nail-in lead anchors; it extends 8 inches underground.

In the end, developing and executing the alternative plan took about two weeks and added $5,000 to the project’s budget. The owners have been happy with the result, and so have we: It allowed us to fill what could have been a painful void in our schedule with profitable work.

Keep the conversation going—sign up to our newsletter for exclusive content and updates. Sign up for free.