Cutting Down

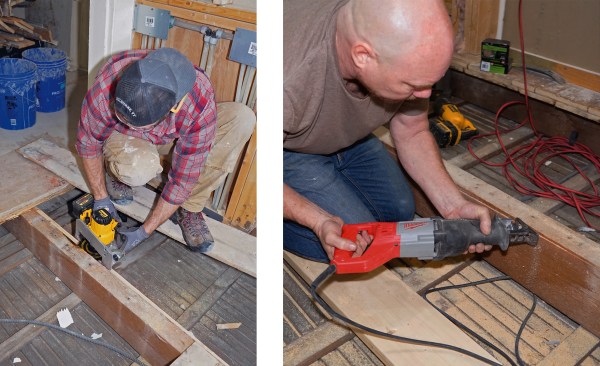

Because the joists were so far out of level, we decided to remove material at the high side and taper down to zero inches, creating a level and flat base to build from. Using a laser level and various beam levels, we found the lowest common point and marked that as zero inches. From there we found level at the far end of each joist, marked and snapped lines, and used jointed lumber as a straightedge and ledger. The ledger was temporarily screwed to the existing joist. We cut as deep as possible with a circular saw, running along the ledger. We finished the cuts with a recip saw, then used a belt sander to fine-tune the cuts.

Hovious rips the joist level with a long angle cut using a circular saw, though the circular-saw blade did not cut all the way through the 3-inch joist (above left). Co-author Warren O’Shea finishes the cut with a recip saw (above right).

O’Shea applies construction adhesive to a ledger header (above left) and screws the header to the existing joist (above right).

Rebuilding

Regardless of finish, our typical buildup beneath tile involves minimum 2×8 floor joists, two layers of plywood totaling 1 1/4 inches, and an uncoupling membrane. Cutting down the joists gave us enough room for this typical tile buildup, as well as in-floor electric radiant heat. The finished-floor height at the doorway over the center wall was 2 1/2-plus inches above the joists. Total buildup will be around 2 3/4 inches (see illustration, previous page).

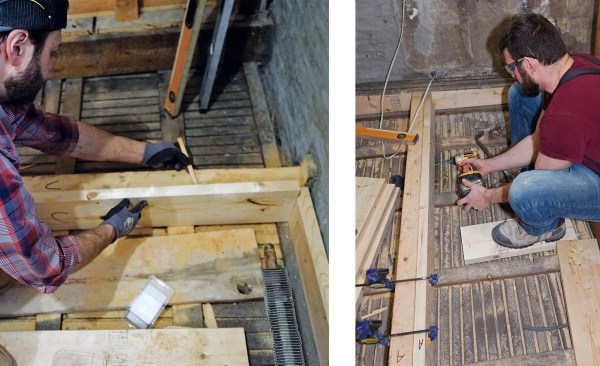

After cutting down the joists, we remortared the original joists into the brick wall, and then sistered them with 2x8s ripped down to the same taper. We installed blocking and framing to bring our joist spacing to 16 inches on-center or less, screwing headers between the original joists to catch new mid-span joists (for good measure, we glued the headers to the original brick). We added new joists under existing walls for support. We screwed and glued all framing with GRK framing screws, 3 1/8 inches or 2 1/2 inches, and PL Premium urethane construction adhesive and used joist hangers where possible. We added blocking at roughly 32 inches on-center to stiffen the floor and create a unified system. See lead photo on previous page.

Hovious scribes a 2×8 sister along the existing joist (above left). Carpenter Mike Raulston attaches the sister (above right).

To improve the efficacy of the in-floor heating, we insulated the voids with R23 and R15 Rockwool insulation. We should achieve roughly R35 below the floor system. (In some places, we had to peel the R15 in half because of the ripped-down joists.) We then installed AdvanTech 3/4-inch subflooring, again using PL Premium urethane construction adhesive and 2 1/2-inch GRK framing screws.

Hovious cuts Rockwool insulation to fit a cavity (above)…

… then splits the batt insulation as needed for thickness (above left). He installs the Rockwool into a joist bay—the joist bays varied in depth (above right).

Subfloor adhesive is applied to a reinforced joist (above left). The AdvanTech subfloor is then slid into place (above right).

The subfloor is fastened down to the floor framing with 2 1/2-inch GRK screws (above).

Next, using shorter, 1 1/4-inch screws, we applied 1/2-inch ACX plywood as underlayment over the 3/4-inch subfloor, running the opposite direction. (We did this to provide a layer of uncoupling from the joists. Uncoupling helps to minimize framing movement telegraphing through to the tile and potentially causing failures.)

All plywood was screwed 6 inches on-center in the field and 3 inches on-center around the perimeter. Once both layers of plywood were finished, new walls were framed in as necessary.

Next Steps

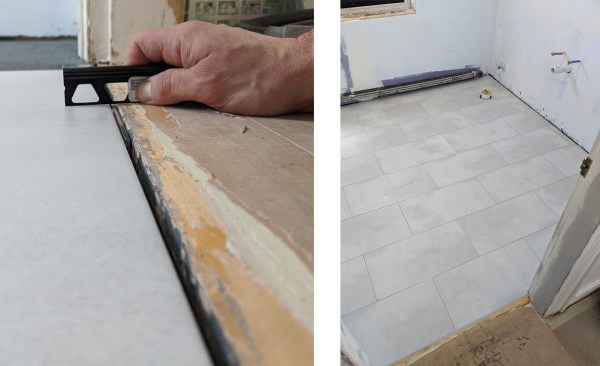

When the plumbing and electrical rough-in was complete, we moved on to the finish process: first setting the tub, then installing drywall and backerboard, and then finally installing the tile buildup. We first thinset and screwed Laticrete Hydro Ban board to the ACX as a thermal break. Then we embedded the heat mat in thinset mortar. After that, we installed the heat wire and skim-coated with thinset. Finally, once all of that was dry, we installed the tile.

The Laticrete Strata Heat mat is thinset to Laticrete Hydro Ban board, the Hydro Ban acts as a thermal break. Heat wire is laid out serpentine-style on the mat’s pegs per the manufacturer’s recommendations (above).

The tile is set in a full bed of thinset using a 1/2 x 1/2" Euro-notch trowel to a 1/4-inch thickness. The thinset is applied slightly thinner at the door to flush the new tile up with the existing floor (above left). The rest of the 12- by 24-inch tile floor is installed level to first row using leveling clips (above right).

Photos by Ted Cushman and Chris Hovious; illustration by Tim Healey