The very first whispers of indoor air conditioning, as we know it today, began around the turn of the last century at The Buffalo Forge Co.—an industrial manufacturer of forges, fans, and blast heaters. There was a reason manufacturing facilities were dubbed “sweat shops” during the industrial revolution, and Buffalo Forge saw an enormous business opportunity in cooling and dehumidifying work environments. Improving the plant conditions would safely extend work hours and increase worker productivity. Buffalo Forge planned to develop a new line of equipment to sell to clients, along with equipment that contributed to sweltering work conditions.

This wasn’t a new business quest. Firms had been in the business of heating, cooling, and dehumidifying plants for decades, but precise control of humidity in a manufacturing environment eluded the industry. The engineer tasked with solving this problem for The Buffalo Forge Co. was 26-year-old Willis Carrier. After being handed the assignment by a senior engineer, J. Irvine Lyle, Carrier landed on the idea of using a spray of water as a condensing surface. By driving humid air through the water spray, he could dry the air; and by adjusting the temperature of the water spray, he could adjust the air’s humidity. The science of psychrometrics had been born.

Image courtesy Carrier Corporation

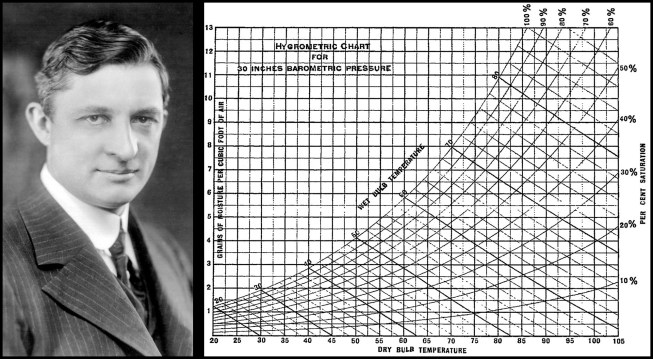

Willis H. Carrier, circa 1919, is pictured here (photo left). The first published version of Carrier’s psychrometric chart (photo right), which he entitled the ‘Hygrometric Chart” (1905).

Carrier dubbed the process “dew point control,” and it was a prime feature of The Buffalo Forge Co.’s new line of industrial “air washers.” In a 1906 catalog, Carrier provided data about his air washer and included the first psychrometric chart. Indeed, the task of explaining to plant managers what he was doing proved as important as what he was able to do. Every successful invention is the product not just of good engineering, but of marketing, as well.

Image courtesy Carrier Corporation

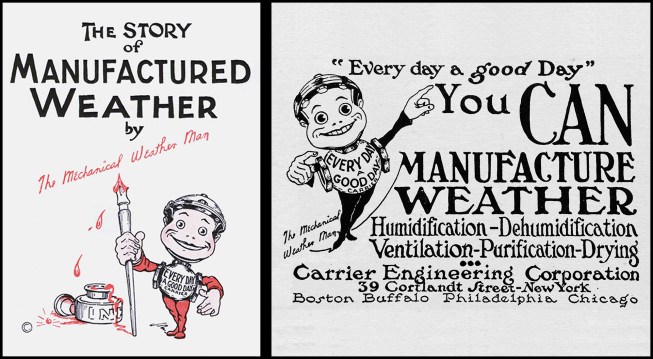

Carrier Engineering Corp.’s early marketing efforts featured a cartoon mascot, The Mechanical Weather Man (aka “Mech”), whose control-valve body touted “Every Day a Good Day” (photo left). In 1919, Carrier hired Esten "Jack" Bolling as their first "Publicity Engineer”. Bolling created “Mech”, coined the terms "Weathermakers to the World" and "Manufactured Weather”, and challenged customers to "Make Every Day a Good Day," a reminder that air conditioning meant efficient production in all weather. A 1921 newspaper ad notes, “You can manufacture weather” (photo right).

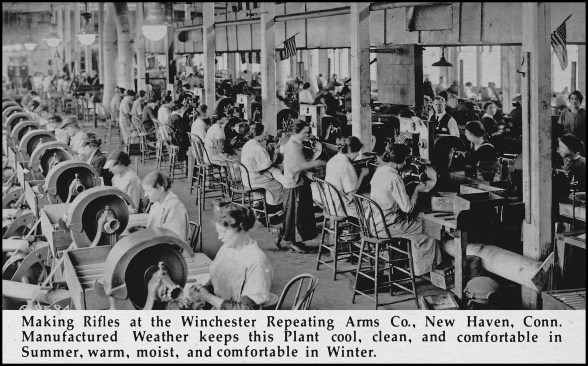

While the business took off, the Buffalo Forge Co. backed off from it when the country entered World War I. As labor and material grew scarce, the company scaled back to its original lines. Carrier and Lyle weren’t ready to abandon the project, and with five other engineers, founded the Carrier Engineering Corp. in 1915. Two years later, the nascent company’s biggest customers were munitions makers who clambered for technology to control indoor humidity, which helped reduce static charges that could touch off explosions around flash powder. Fuses and some explosive compounds in bomb manufacturing could not be produced in unstable indoor environments. As the war progressed, air conditioning in textile plants and candy factories also proved lucrative. After the war, food processing plants became the next big market for “manufactured weather.”

Mech “authored” his own book (“The Story of Manufactured Weather”) in 1919, featuring testimonials from satisfied customers (photo excerpt depicting “comfortable” workers manufacturing firearms during World War I).

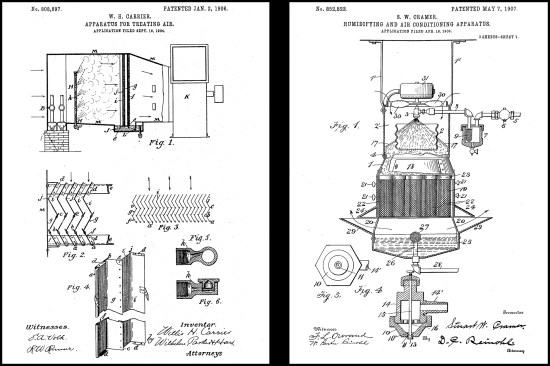

Curiously, the term “air conditioning” was not Carrier’s. Carrier filed his first patent as “An Apparatus for Treating Air.” “Air conditioning” was a phrase used on a different 1906 patent, filed by Stuart Cramer, a textile engineer, for a device specifically designed to condition yarn.

Carrier’s “Apparatus for Treating Air” patent submission for his industrial “air washer” (photo left). Cramer’s “Humidifying and Air Conditioning Apparatus” was a major contribution to the textile industry (photo right). Spinning efficiency of cotton was greatly improved via his invention’s use of a water-spray humidifier to control relative humidity levels, reducing yarn breakage and improving worker comfort levels.