Editor’s note: This article was first published in 1993 and is a companion article to “The Last Word (We Hope) on Vapor Barriers.” It is reproduced here for archival purposes. More up-to-date coverage of details can be found on JLC’s Air Sealing page.

While much attention is given to vapor barriers, research suggests that air sealing is much more important.

Laps between pieces of a poly air/vapor barrier should be sealed with a tape made specifically for polyethylene sheeting, such as 3M Construction Tape. This is widely distributed with DuPont’s Tyvek. Similar tapes are available from Sto-Cote and Yunkers.

[Editor’s note: Since this article first appeared, there are a number of construction tapes, notably those from Pro Clima and Siga. And these days the focus for air sealing is not so much on taping an air/vapor barrier membrane, as it is on taping over junctions directly on framing and foundation materials. For guidance see “Testing Flashing Tapes,” Aug 31/2017.]

Window and door openings. Many builders still stuff the gap between the rough opening and a window or door with fiberglass insulation even though fiberglass will not stop air. Non-expanding foam sealant is a much better choice. (If you use expanding foam, use a light touch, or the foam can over expand and push the jambs outwards.)

[Editor’s note: These days, non-expanding can foam is available and should always be used.]

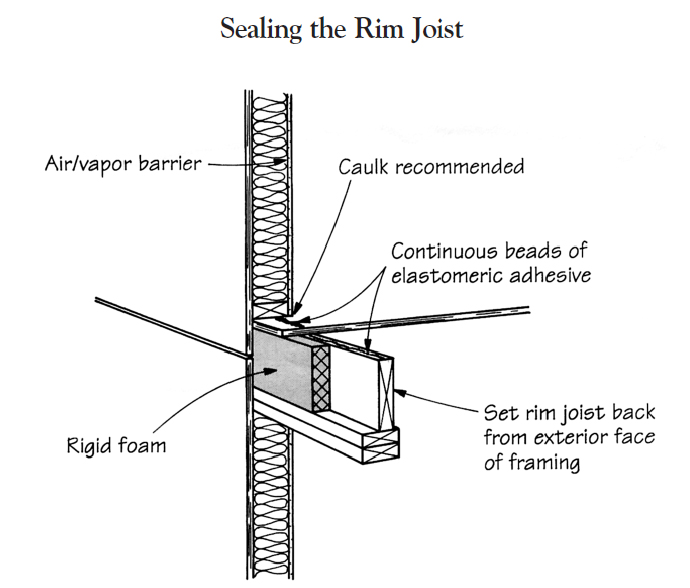

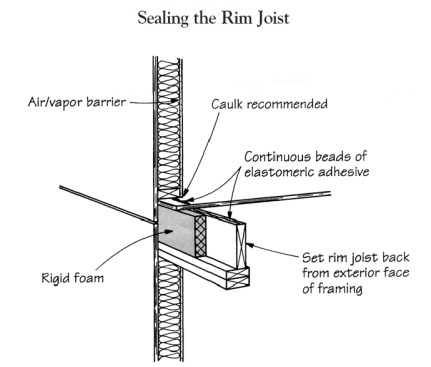

Band joists. Sealing a second-story band joist is particularly hard — because unless you wrestle with the poly while you’re framing, it’s nearly impossible to get a continuous seal. The best solution we’ve seen is to inset the second-story band joist and run a strip of rigid insulation on the outside. This keeps the band joist area warm, so that it’s not prone to condensation (see illustration below). For very cold or windy sites, you can improve upon this by adding a strip of housewrap around the band joist. Tyvek is available in 3-foot-wide rolls for this application. In colder climates, a tight band joist is critical for keeping blasts of cold air out of the floor system.

Instead of wrapping the vapor barrier around the band joist, you can insulate the band with rigid foam so that it’s not prone to condensation.

Plumbing. Where pipes run into exterior walls, seal them to the air/vapor barrier with construction tape, or seal the opening around the drywall with spray foam. Plumbing stacks that run from a basement into an exterior wall are often ignored. Foam around the opening through the framing.

Electrical boxes. There are a number of products available for ensuring a tight seal around electrical outlet and switch boxes in exterior walls:

A Lessco Air-Vapor Barrier Box (Low Energy Systems Supply Co., 990 Mink Ln., Campbellsport, WI 53010; 414/533-8690) nails to the wall framing before an electrical box is installed. The box is sealed by caulking the small holes for incoming wires and taping the poly air/vapor barrier to the box’s wide flange.

Another option for new construction is to use a plastic electrical box with a flange. Some of these, like the Thermoplastic line from from Barnett (www.barnett.com) have a foam-gasketed flange that is meant to press up against the back of the drywall and provide a tight seal without a plastic air/vapor barrier. Other, like those from , such as those from Airfoil (airfoilinc.com) have a wide ungasketed flange that provides a good surface for sealant to bond to.

Recessed light fixtures. Because the lights are hot they act like small chimneys to draw moist air into the ceiling cavity. Use airtight ceiling fixtures. These are IC-rated so you can pack insulation close around them, and are sealed so they have a very low air leakage rate.