Conventional vented attics are one of the most obvious places to increase insulation values: Once you’re set up to blow fiber into the attic, piling the material a little deeper is easy.

Noel Hardin

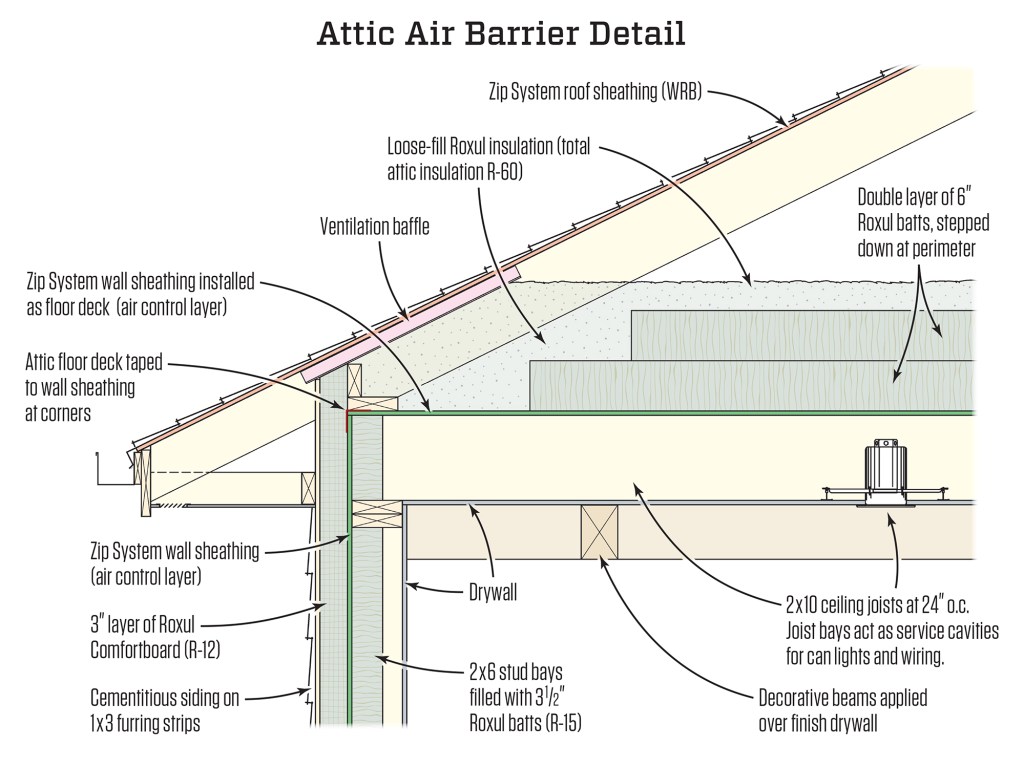

The Zip System sheathing on the attic floor creates a tight air seal.

Noel Hardin

The stick-framed-attic volume is reserved for blown cellulose insulation, with no storage or equipment; here, the architect and builder discuss the ventilation strategy while they still have access to the space.

Air-sealing is a different story, though. The drywall ceiling below a vented attic is usually perforated by ceiling light fixtures, bathroom vent fans, plumbing vents, and wiring penetrations at partition wall plates. When you’re working from above, the attic floor can be one of the most complicated and laborious locations to air-seal in the entire house.

So while the air control layer and the thermal control layer for the whole envelope should, in principle, line up, putting that principle into practice in the attic can be a tedious, time-consuming pain in the neck—and, perhaps for that reason, is often accomplished imperfectly, at best.

Chris Laumer-Giddens

Beneath the attic floor, the 2×10 joist cavities provide a convenient service chase that easily holds recessed lighting fixtures inboard of the air barrier.

Chris Laumer-Giddens

Continuous exterior insulation boosts the wall R-value.

Architect Chris Laumer-Giddens, of LG Squared, says he has a simpler way to build an airtight lid. Last year, Laumer-Giddens designed a 2,700-square-foot high-performance home in the western North Carolina mountains. To construct the ventilated attic for the house, builder Brett Murphy built a joist system on top of the second-story walls just as you might frame a second-story floor deck, using 2×10 lumber. Murphy decked the floor with Zip System sheathing, then stick-framed the roof above that solid platform.

The result is a near-perfect air barrier for the attic, with an ample service cavity below it for can lights and wiring. As a side benefit, Laumer-Giddens says, “During construction, the framers were almost giddy about how this platform made their job of stick-framing the roof so much easier.”

Tim Healey

The stick-framed ceiling assembly allows a continuous insulation layer that aligns perfectly with a fully sealed air barrier, isolating the living space below from the unconditioned, fully ventilated attic above.

The home’s wall system integrates neatly into the attic floor (see Attic Air Barrier Detail, previous page) simply by taping the Zip System wall sheathing to the attic floor’s Zip System deck. Outboard of the taped sheathing, the walls received a 3-inch (R-12) layer of Roxul rock wool; the stud bays are insulated with R-15 Roxul batts, for a wall system R-value of about R-27.

Laumer-Giddens specified R-60 Roxul insulation (a layer of batts topped with blown fiber) for the attic, but he says, “Once they got in there with the blower, I think they probably got closer to R-80.” The near-perfect wall and lid air control layer helped the house score a blower-door test of 0.5 ACH50 before insulation and drywall. The final blower-door number was even better: 0.25 ACH50. Laumer-Giddens plans to perform another blower-door test in six months, to verify that the house is staying tight, with another follow-up test a year after that.

The home heats and cools with a single 2-ton ducted mini-split heat pump, with all ductwork kept within the conditioned space. And after living there through one full winter and most of a summer, the homeowner reports electric bills of less than $100 a month.