Controlling moisture problems is difficult in climates where seasonal changes call for both heating and cooling of interiors.

In addition to common concerns about rain penetration through exterior cladding, builders in a mixed climate must take special precautions to prevent moisture from becoming trapped in wall and roof cavities — a problem that is complicated by high humidity levels both inside and outside the structure.

Infiltration & Exfiltration

During heating periods, when interior air pressure is high, humid air inside the building is driven outward, either by air leaks into wall and roof cavities (exfiltration) or by diffusion (passage of water vapor through permeable materials). If roofs are not properly ventilated and if walls are not allowed to dry, this moisture can cause decay in structural framing members.

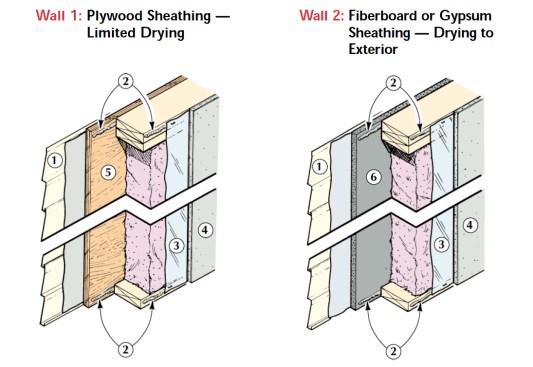

Both Walls:

- The rain screen principle controls rain penetration when vinyl or aluminum siding is used. Building paper controls rain absorption into the sheathing. 1

- Air movement is controlled with an air-flow retarder formed by using caulk to seal the exterior sheathing and the polyethylene on the interior to the framing. 2

- The polyethylene sheet placed beneath the gypsum board acts as a vapor diffusion retarder. 3

- Any paint or wall covering (permeable or impermeable) may be used. 4

Wall 1:

- Uses impermeable, noninsulating sheathing (plywood or OSB). 5

- Drying of the wall is limited, so framing and insulation materials should be dry at installation or permitted to dry before enclosure.

- Also suitable for wood siding, using the barrier approach, in which all openings are sealed. (An alternative to the barrier approach is to use wedges or oval-head nails to allow air to move between pieces of siding, or to install the siding over furring.) All materials must be dry, and the siding must be back-primed and fastened according to the manufacturer’s recommendations.

Wall 2:

- Sheathed with permeable asphalt-impregnated fiberboard or gypsum. 6

- Drying is to the exterior

The situation is reversed during cooling periods. Mechanical cooling and dehumidification cause the vapor pressure to be higher outdoors than indoors, driving humid outside air inward (infiltration). In fact, vapor pressure differences during cooling periods in this climate can be more significant than those found during heating periods. The high inward flow of moisture during cooling periods can increase cooling loads and the corresponding energy costs, as well as increase building deterioration.

Moisture problems during cooling periods are compounded by cladding systems such as brick, masonry, wood, and stucco, which can absorb significant amounts of rain. As solar radiation warms exterior wall surfaces, lower interior temperatures serve to drive moisture inward, where it can condense on surfaces cooled by air conditioning. An example of this is the potential for moisture damage to drywall covered with vinyl wallpaper on the interior of a masonry block wall. Without a vapor retarder (to inhibit diffusion) and an air-flow barrier (to stop air movement), the drywall is not protected from humid outside air or from moisture that may be trapped in the masonry units.

Construction moisture — moisture present in the building materials themselves — merits special attention in mixed climates. Building assemblies constructed with wet lumber (greater than 19% moisture content by weight) or employing wet-applied insulation (wet-spray cellulose or blown fiberglass) must be designed so that they can dry to the exterior or interior, or the construction materials must be allowed to dry prior to being enclosed.

- Brick veneer covers wood-frame wall. 1

- A 1-inch air space between the brick and the woodframe assembly is a receptor for capillary moisture and absorbed moisture driven inward by solar radiation. 2

- Drying is to the exterior, through permeable noninsulating sheathing. 3

- The building paper must be continuous and well-fastened to prevent wind action from “pumping” moisture to the interior. 4

- The poly sheet on the interior acts as vapor diffusion retarder. 5

- Any interior finish (permeable or impermeable) may be used. 6

Condensation

Improved airtightness of buildings in mixed climates tends to reduce the number of air changes during the heating season. This can lead to elevated interior levels of moisture, which not only contribute to condensation within walls and roof spaces, but cause condensation on window surfaces and give rise to surface mold and mildew as well.

During the heating months, interior surfaces cooled by thermal bridges or other thermal defects (such as wind blowing through insulation) create high interior surface relative humidity at these locations. The result is localized mold and mildew growth, typically where exterior walls intersect insulated ceilings, at exterior corners, and at uninsulated or poorly insulated window lintels or headers.

Each of the six wall assemblies illustrated here is designed to address the special moisture problems associated with a mixed climate, including rain penetration and absorption, air movement, water vapor diffusion, drying, and interior finishes.

Rain Penetration

All but one of the six wall assemblies recommended for this climate use the rain screen principle to control rain penetration. (Wall 5 uses the barrier approach, discussed below.) In a rain screen, a space behind the siding serves to equalize pressure on both sides of the cladding. The cavities behind vinyl or aluminum siding, for example, accomplish this, so long as they are not blocked or filled with insulation.

In an effective rain screen, the exterior sheathing must be significantly tighter than the cladding. Thus, the sheathing should be installed vertically, with all joints falling on framing members. For additional airtightness, apply a sealant or adhesive at sheathing joints and edges. Alternatively, install a tight layer of 15-pound felt paper with lapped or taped joints.

With a brick veneer (Wall 3), form the rain screen by creating a minimum 1-inch air space between the brick and tight fiberboard or gypsum sheathing. To allow inward air movement to equalize pressure, this air space must be clear of mortar droppings and should be open at the top; leaving open every other vertical mortar joint in the first course of brick at the base also lets in air, and provides weep holes for drainage as well. If you use a continuous layer of building paper to further tighten the sheathing, be sure to fasten it extensively to prevent flexing under wind action, which could pump moisture into the assembly.

To direct cavity moisture to the exterior through the weep holes, extend flashing at the base of the brick to the back of the rain screen cavity and place it behind the sheathing or building paper. Careful installation of flashing over window and door openings is also critical in all rain screen assemblies. Ideally, the flashing should be tucked behind the sheathing or building paper to direct rainwater to the exterior of the assembly.

Barrier approach. With stucco, rain penetration is controlled using a barrier or face-sealing approach. Make sure the stucco is continuous and sealed at all openings, such as at windows and doors. To prevent cracking, use control joints, taking care to apply a bond breaker between the stucco and any sheathing material. In Wall 5, the bond breaker is the face of the rigid foam sheathing itself; sheet polyethylene and building paper also are effective bond breakers. In the absence of a bond breaker, space the control joints closer together. In any case, carefully flash and seal the control joints to reduce entry points for rainwater.

Wood-based siding. You can use the barrier approach with wood-based siding, applying the siding directly over building paper that is lapped or taped over plywood or OSB sheathing. Alternatively, you can create a rain screen by applying the siding to furring strips, or by using wedges or oval-head nails to create gaps between pieces of siding. In either case, prime all surfaces of the siding and fasten it according to the manufacturer’s recommendations.

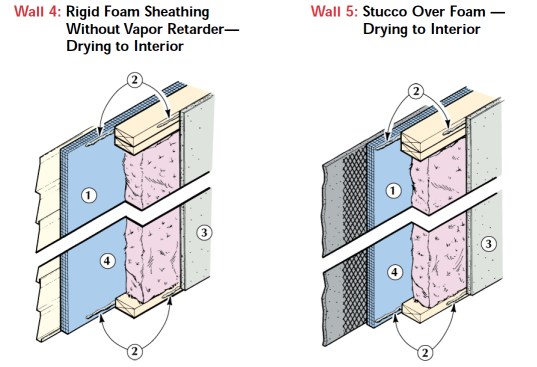

Both Walls:

- Impermeable rigid insulation used as sheathing acts as a vapor diffusion retarder for vapor entering from the exterior during cooling periods. This limits potential condensation by raising the wall cavity temperature. Building paper is not needed, since the rigid insulation controls rain absorption and capillary suction. 1

- Air movement is controlled with air-flow retarders formed by sealing the exterior sheathing and the interior gypsum board to the framing. 2

- Permeable latex paint on the gypsum board permits interior vapor to enter the wall and then dry to the interior. No vapor diffusion retarder is needed on the inside of the wall. 3

- Drying depends on several factors: 2×4 wall construction.

- Interior relative humidity must not exceed 35% at 70°F during heating periods.

- Cavity insulation must be limited to R-11, while the rigid insulation must be at least R-7. 4

Wall 4:

- Rain screen principle controls rain penetration.

Wall 5:

- Barrier approach controls rain penetration.

- Exterior cladding is stucco over galvanized lath, applied over rigid foam sheathing. 5

Rain Absorption

With vinyl or aluminum siding, the building paper keeps the exterior sheathing from taking on moisture, either directly through absorption or through capillary suction. Where rigid insulation is used as sheathing, its impermeable surface serves the same purpose, so building paper is not required.

With stucco cladding, the formulation and material properties of the stucco itself are important. In traditional threecoat stucco, each successive layer to the exterior is weaker and more permeable than the layer under it. The result is that the farther water penetrates into the wall, the more resistance it meets; and once water has penetrated the stucco, this layered effect makes it easier for moisture to migrate toward the exterior than to penetrate any farther to the interior.

For the same reason, any paint or sealant should be more permeable than the outermost surface of the stucco itself. This is very difficult to achieve in practice, however, so you will have more success with stains or colorants added to stuccos during application than with paint films applied after the stucco cures.

With a brick veneer, the air space behind the brick controls both rain absorption and capillary suction. The air space also acts as a receptor for moisture driven inward by incident solar radiation. (The same principles are at work in wood-based siding applied to furring.) To further protect the sheathing, install a layer of building paper over the sheathing.

Air Movement

In a mixed climate, air may transport moisture inward from the exterior during the cooling season or outward from the interior during the heating season. To control this moisture, create an air-flow retarder at either the interior or exterior of the wall. (When possible, provide an airflow retarder on both sides of the wall.) In most cases, use a continuous sheet of 6-mil polyethylene to create an interior air-flow retarder; on the exterior, you can use adhesive or caulk to seal the sheathing to the framing. Asphalt-impregnated fiberboard sheathing has proved difficult in practice to seal to the framing. If you use this material, locate the airtight plane on the interior side of the wall, and cover the sheathing with a continuous layer of permeable, nonabsorptive building paper to create an exterior air seal.

- Rain screen principle controls rain penetration.

- Impermeable rigid insulation used as sheathing acts as a vapor diffusion retarder for vapor entering from the exterior during cooling periods. The sheathing also controls rain absorption, and eliminates the need for building paper. 1

- To control air movement, the exterior sheathing and the interior gypsum board are sealed to the framing to form air-flow retarders. 2

- Insulating sheathing raises the wall cavity temperature and limits potential condensation.

- The facing material on the cavity insulation acts as a vapor diffusion retarder on the interior. 3

- Drying is limited, so framing and insulation materials should be dry or permitted to dry before they are enclosed.

- Any interior surface finishes (permeable or impermeable) may be used. 4

- Vinyl, aluminum, or wood-based siding may be used.

- With wood-based siding, all materials should be dry during installation, and the siding should be back-primed and fastened according to manufacturer’s recommendation. 5

Vapor Diffusion

Water vapor can also move by diffusion both from the inside outward and from the outside inward, depending on the season. To protect against vapor diffusion from the interior during heating periods, you can use one of two approaches. The first method is to install a vapor diffusion retarder at the interior of the wall. In Walls 1, 2, and 3, this consists of a continuous polyethylene sheet; in Wall 6, the facing on the cavity insulation serves the same purpose.

In the second approach, vapor from the interior enters but does not accumulate in the wall assembly, because the temperature within the wall is deliberately elevated. This limits the amount of condensation that can accumulate on the cavity side of the exterior sheathing.

No vapor diffusion retarder is used in Walls 4 and 5, for example. Instead, the thermal resistance of the insulating sheathing limits periods of potential condensation so that wood decay does not begin and waterstain marks or mold or mildew do not appear on interior surfaces. The insulating sheathing should be R-7 or greater, and the cavity insulation should be R-11 or less. Interior moisture levels during heating periods should also be limited to 35% relative humidity at 70°F.

Cooling periods. Impermeable sheathing, such as plywood, waferboard, or OSB, acts as an effective vapor diffusion retarder, and controls vapor diffusion from the exterior during cooling periods. Rigid foam insulation installed as exterior wall sheathing serves the same purpose.

Alternatively, you can install a continuous polyethylene vapor retarder at the interior of the wall assembly, as shown in Walls 2 and 3. (Foilbacked interior gypsum board and Kraftfaced cavity insulation may not be effective due to gaps at the joints.) Although this approach does not prevent moisture from entering the wall from the outside, the vapor diffusion retarder effectively protects the drywall and any interior finishes from moisture damage. Any moisture driven inward during the day may condense on the cavity side, but typically it migrates outward in the evening when the temperature gradient reverses.

Drying and Interior Finishes

Which wall detail you use depends in part on what kind of materials you will use to frame and insulate. If your framing lumber has a moisture content greater than 19%, or if you intend to use wet-applied insulation (such as wet-spray cellulose), either avoid walls with limited drying ability (Walls 1, 2, and 6), or allow the entire assembly to dry before closing it in.

This is not a concern with Wall 3, in which the vapor-permeable sheathing helps the wall dry toward the exterior, while the air space between the brick veneer and the sheathing acts as a receptor for interior cavity moisture.

Any kind of interior surface finishes may be used in Walls 1, 2, 3, and 6, since drying to the interior is limited. In Walls 4 and 5, however, a vapor-permeable interior surface finish is required to permit drying to the interior. Keep in mind that where a permeable interior surface, such as painted drywall, is subsequently covered with an impermeable interior material, such as vinyl wallpaper, mold and mildew may appear.