Q: A client has hired me to build a large outbuilding with a single-plane shed roof. How do I weatherproof the uppermost edge?

A: Mike Guertin (on Instagram @mike_guertin), a builder and remodeler in East Greenwich, R.I., and a presenter at JLC Live, responds: We framed and roofed a number of contemporary homes in the 1970s and 1980s with mono-slope (aka mono-pitch) roofs. Back then, local lumberyards stocked mono-slope ridge flashing that looked like oversized drip edge. But instead of being installed before the roofing (in the usual drip-edge fashion), mono-slope flashing is installed with the roof leg on top of the roofing and the vertical leg extending down over the fascia.

Mono-slope ridge cap flashings are still fabricated by flashing manufacturers and can be found online, but the lumberyards in my area no longer stock those flashings. Rather than wait for a special order, I make my own—mono-slope ridge flashing is easy to make on a sheet metal break (see “Using a Sheet Metal Brake,” May/17).

I start with regular colored aluminum coil stock 0.019 inch thick or thicker (galvanized, copper, or stainless steel can also be used). Standard sizing calls for a 6-inch-wide roof leg and a 4-inch drop leg with a 1/2-inch drip bend at the bottom. I hem the 6-inch edge and the 1/2-inch drip bend to stiffen the flashing and minimize oil-canning when it expands. I adjust the angle between the roof and drop legs to match the slope of the roof.

I often form an extended edge of the roof leg of the flashing (similar to the projection found on most drip edges). The projection is mainly cosmetic, creating a shadow line along the ridge, and doesn’t improve the water resistance of the flashing.

Tim Healey

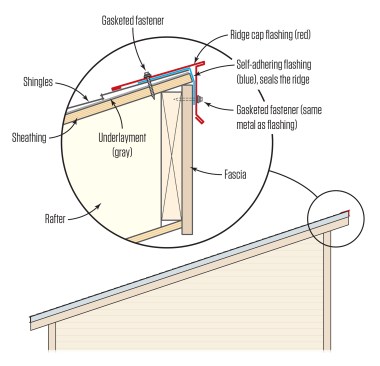

Custom-bent flashing (photo) and self-adhering flashing weatherproof the top edge of a mono-slope roof. Gasketed fasteners hold the flashing in place.

I install the flashing over the roofing (such as asphalt shingles) along the ridge, with the roof leg face-nailed or screwed down. Ideally, you should use the same metal for the fasteners and the flashing—aluminum fasteners with aluminum flashing, galvanized steel with galvanized steel—to avoid corrosion due to galvanic reaction. If you’re concerned about the flashing leaking at the fastener penetrations, you can use gasketed fasteners commonly used to fasten metal roofing.

If you’re in a high-wind area, I recommend applying a 4-inch strip of self-adhering flashing (SAF) tape to help seal the roofing to the fascia. The ridge flashing then goes over the SAF. In the event that wind-blown rain makes its way under the drop leg of the ridge flashing, the flashing tape will block the water. You can also nail the drop leg to the fascia board for extra hold-down.