In finish carpentry, where time is limited and material costs are high, the quality of your tools can significantly affect the outcome of a job. One often-overlooked component is the miter saw blade—especially when clean, polished cuts are required across a variety of materials such as hardwoods, moldings, and veneered plywood.

Key Features to Look For

When selecting a finish blade for your miter saw, it’s worth considering several features that can enhance cut quality and overall efficiency:

- Carbide Teeth: High-density carbide formulations extend blade life and stay sharper longer, reducing the need for frequent replacements.

- Precision Grinding: Look for blades with advanced grind geometry, such as axial shear face grinds or double side-grind teeth, which can help minimize tear-out on delicate materials like melamine and laminates.

- Ultra-Thin Kerf: A thinner kerf reduces resistance, allowing for smoother, faster cuts. This is especially useful for battery-powered saws, as it can help conserve energy and extend tool run-time.

- Laser-Cut Design: Laser-cut plates and expansion slots reduce vibration and improve blade stability, contributing to more accurate cuts.

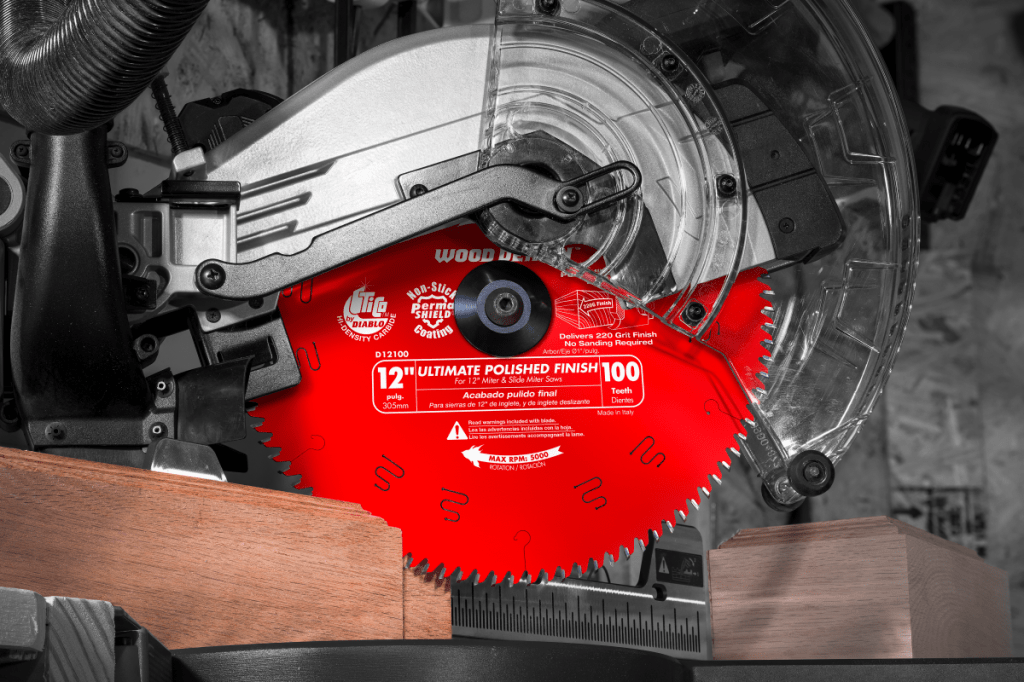

Introducing Diablo’s Wood Demon Blade

Among the high-performance blades available today, Diablo’s Wood Demon 12″ x 100-Tooth Ultimate Polished Finish Saw Blade stands out for finish carpentry applications. It combines several advanced features that contribute to cleaner cuts and greater jobsite efficiency. At the core is Diablo’s proprietary TiCo Hi-Density Carbide—a custom blend formulated to stay sharper longer and hold up under demanding conditions. The blade’s Axial Shear Face Grind (ASFG) helps minimize chip-out in materials like melamine and veneered plywood, which not only improves the quality of the cut but also reduces waste and time spent on touch-ups.

Each tooth features a double side-grind geometry designed to leave behind an ultra-smooth surface, comparable to a 220-grit sanded finish—ideal for trim and cabinetry work. The blade also employs an ultra-thin, laser-cut kerf that makes cutting faster and more precise with less resistance. This not only improves cut quality but also helps conserve battery life when used on cordless miter saws.

With these combined features, the Wood Demon delivers a professional-grade solution for carpenters seeking consistently clean, polished results across a range of materials.

What the Pros are Saying

Contractor feedback on the Wood Demon D12100X has been very positive. The Wood Demon is a blade that delivers efficiency to contractors who need precise and clean cuts across a variety of materials such as fine molding, hardwoods, softwoods, and veneered plywood.

One of the other points mentioned by users is the reduced need for frequent blade changes. This is significant as it makes the jobs a little bit easier without the stress of consistently changing blades. Contractors also say the efficiency of the ultra-thin kerf design allows for quicker cuts and helps produce less waste, making it a valuable money and time saving tool.