Pocket-hole joinery has been a staple in cabinet shops for decades, and with good reason. Tests show pocket holes and screws to be superior to traditional joinery in 3/4-inch material. For example, a comparable mortise-and-tenon joint fails at about 450 pounds under a shear load, whereas a pocket-hole joint fails at around 700 pounds. With the portable jigs available everywhere these days, they have become almost universal in the woodworking and DIY world.

My first pocket-hole jig was the clamp-on 2-hole style. I soon moved up to the manual bench top model with which I subsequently cut thousands of pocket holes (check out this different pocket hole jig here). As a result, I learned to be pretty proficient. However, I had my eye on an automatic bench top model. Disappointed with the plastic homeowner-grade machines I was finding plenty of, I started doing some research for an alternative.

What I found was a company after my own heart: Castle Tools have been made in the same Petaluma, Calif., plant since the 1980s and all of its machines are painted John Deere Green “as a nod to American ingenuity.” Sold!

Add to that the machine is all steel and built like a tank. Castle is a company that hasn’t succumbed to the temptation to move manufacturing overseas nor join the race to the bottom by cheapening its products to pad its bottom line.

This part is important. It gets its own line: This is the kind of company I want to reward with my dollars.

When my TSM12 arrived, it was shipped so well that it took a solid 10 minutes to cut away all the packing foam, shrink wrap, and tape from the individual parts. I mention this because I have received tools so poorly packaged for shipping that the mess of damaged parts I’ve received was inevitable from the moment they were put in the box.

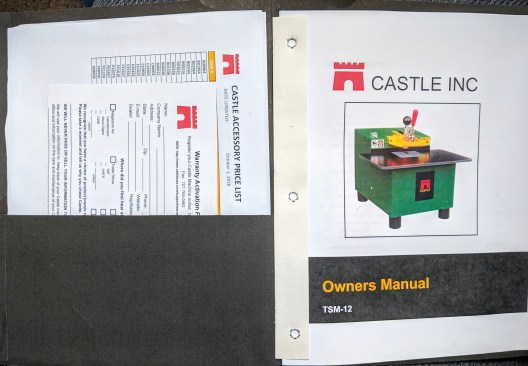

As I was putting the machine together, I admired how heavily built everything is. Even the U-bolt that holds the cutting router in place was overly large, which I like. The instructions, warranty info, and other miscellaneous literature came in a 3-ring-binder-type folder [Editor’s Note to Generation Gray: Maybe the Castle binder was inspired by another 1980s (or 70s) legend, the Meade Trapper Keeper]. The majority of it seems to have been printed in Castle’s office on a desk jet; the holes punched and folder pockets stuffed by hand. Yet another layer of Castle’s process I find insanely cool. Perhaps it just seemed more personal than the typical mass-produced instructions I’m used to seeing.

A different way to make pocket holes

The Castle uses a rather unique setup to cut its pocket holes, using two Bosch routers. This one cuts the pocket and this one drills the pilot hole. You simply push the lever forward to cut the pocket and pull it back to drill the pilot hole. The whole process takes just a few seconds with repeatability that you just can’t get with a manual jig.

What I like best about this setup is, should a router ever fail, I can easily go to a big box and get a replacement that day. That, to me, is peace of mind I wouldn’t get from a unit with a proprietary motor. In fact, given today’s throwaway culture, I’d almost bet it would be cheaper to buy a whole new machine than to replace a motor on one of the other commercially available units.

If you’re only used to the Kreg style of pocket holes, you’ll find another feature to love about the Castle: The holes are cut at an angle less than half (6 degrees vs.15 degrees) that of the Kreg. With that change, you’re not only more in plane with your mating piece—lowering the chance of the two slipping apart when screwing—but you also leave more wood fiber surrounding the screw. This translates to a stronger joint. Castle offers several styles of precut plugs for these holes, including an easily removable plastic plug that is actually quite attractive.

Dust collection

As shipped, the TSM12 is not ready for dust collection. The bottom is wide open, allowing access to the internals for setup. However—add another point in the cool column—the company sends a template to cut a base from plywood if you desire to do so. Once you have the bottom in place, there are two knockouts on the back of the machine for connecting either a shop vacuum or 4-inch collection hose.

I have been very pleased with my TSM12 since owning it. It increases my efficiency, which in turn increases my bottom line. Given how well it’s built, I also enjoy the confidence of knowing I will get a lifetime of service from it, and that isn’t something I can say about every tool I own.

Castle TSM12 Bench Top Pocket Hole Cutter MSRP $1,170

Includes:

- Bosch 1617 Router

- Bosch Colt Router

- 9/64” premium drill bit

- 3/8” three-flute solid carbide router bit

Technical Specifications:

- Router: Bosch 2.0hp #1617 Router Motor

- Router Bit: Premium 3/8” Solid Carbide, Rough Mill

- Drill: Bosch Colt 1.0hp #PR20EVS trimmer motor

- Drill bit: 9/64” Brad and Spur Premium TiN-Coated Bit

- Power req:110 VAC, 15 amps

- Shipping weight: 60 lb.

- Footprint: 13.5W x 20L x 20H

Enhanced Features:

- Castle’s patented low-angle pocket

- Wider throat opening for thicker stock

- Dust collection ports

- Openings for shop vacs

- Solid surface work top

- Improved clamping