Powermatic

As enclosed cabinet saws go, the PM1000 is very compact – abou…

Last week I was in Nashville for the unveiling of the PM1000, a new saw that made me wish I could trade my old saw in. And I already have a really nice saw (a 15 year old Powermatic 66); it’s just that it takes up a lot of space and is more saw than I need for the work I do now.

The PM1000 is essentially a downsized version of the PM2000, a 10-inch enclosed cabinet saw that has been out for 7 or 8 years. This new model has two claims to fame: It’s very compact and has a 1 3/4 HP motor that comes wired for 115 volts (it can be converted to 230 volts).

For some, this will be the difference that allows them to use a high quality machine in a small workspace or in a shop that is not wired for 230 volts. It also makes it easier to bring the saw onto a jobsite – though frankly, few people will because at 350 pounds the PM1000 is not very portable. Still, for those contractors who set up on site for a very long time, the 115-volt wiring will make this machine a more viable option.

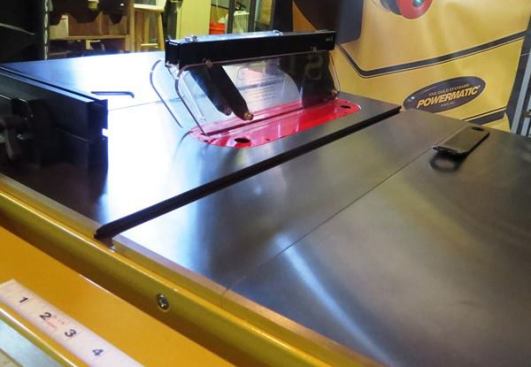

The Powermatic pedigree of the PM1000 goes deeper than the distinctive gold paint. It has a nicely machined cast-iron top, heavy cast trunions front and back, a TEFC motor, and the heavy hand wheels one expects from the brand. Upgrades over previous generations of Powermatics include: a switch that is easily turned off with the bump of a hip or knee, and arbor lock for changing blades, and an adjustable fence on the miter gauge. The saw is equipped with an Accu-Fence, a simple solid rip fence that rides on a single heavy rail and locks in place by a lever-operated cam.

One of the more interesting parts of the saw is hidden below the table. The blade is almost totally enclosed within a dust shroud that is piped to a port on the back of the machine. Instead of pulling air from the entire cabinet – which must remain leaky if the motor is to be able to cool itself – air is pulled from around the blade only so less dust escapes.

The saw can be used with the included modular guard, splitter and pawls, splitter alone, or the old-fashioned way – with no protection at all. Powermatic refers to the splitter as a riving knife, but it can’t be adjusted down for non-thru cuts so it’s not a true riving knife. It’s also worth noting that the splitter is too thick for use with thin-kerf blades. That would not be a problem for me, because with a saw like this I would not feel the need to use thin-kerf blades – which are designed to lessen the demand on underpowered machines.

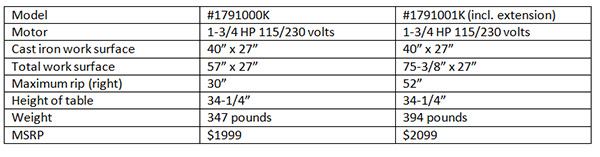

The PM1000 is available with and without an extension table(specs and pricing below).