“To produce safe buildings for the greatest economy and good of the public.” Echoes of this sentence (from the 1927 Uniform Building Code) still ring true in today’s International Residential Code (IRC), which states, “… to establish minimum requirements to safeguard the public safety, health, and general welfare through affordability, structural strength …” (2018 IRC, Section R101.3). Everyone knows the code is the minimum standard and probably understands that its goal is to keep construction affordable. However, code has somehow taken on a negative connotation, as if a structure built to code is cheap or unsafe, or that a contractor known as building “to code” is a hack.

But I think that’s the wrong way to look at the IRC, especially when it comes to decks. Its provisions aren’t a best practices guide to building the “best” deck, but they are a terrific resource for building affordable, sufficiently safe decks.

As a code professional, I believe in safety, but I recognize that safety needs to be available to everyone, and minimum standards provide for maximum deck ownership. For builders looking to tap into the huge budget-deck market, here are some safe, respectable, and sensible strategies for building code-compliant decks that will maximize the client’s dollars.

Cantilevering the Joists

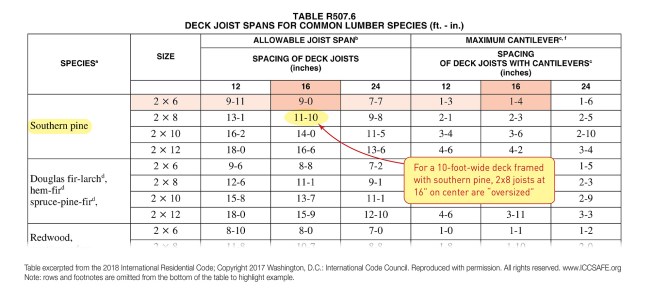

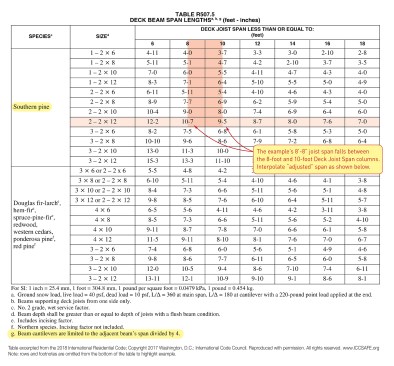

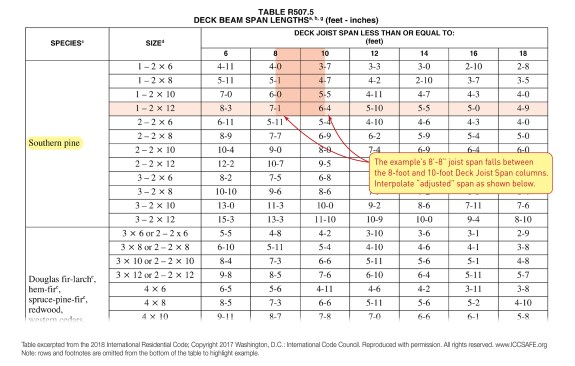

The IRC provides tables for sizing joists (see Table R507.6, below) and beams (see Table R507.5, facing page), which are based on the span of deck joists. The longer the joist span, the more load the beam carries and the shorter its span. Note that beams are being sized for the maximum allowable cantilever of the joists beyond the beam, whether they cantilever or not. If you are not cantilevering joists, you are probably oversizing both your joists and your beam.

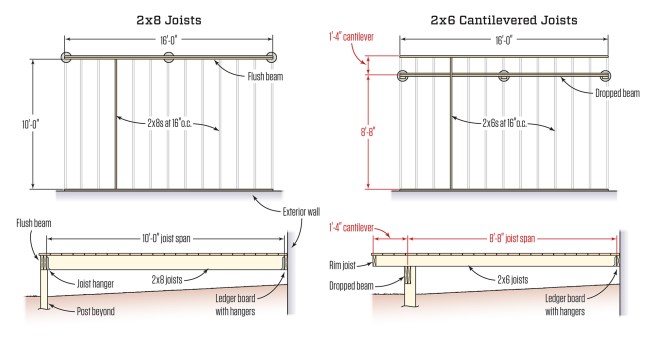

Lesson: Design joists to cantilever past the beams and you shorten the joist span. A shorter joist span allows you to use a different column in the table when sizing the beam—which in turn results in a smaller beam size. For example, instead of using 2x8s hung from a flush beam to build a 10-foot-by-16-foot deck, you can install 2×6 joists—which can span 8 feet 8 inches with an additional 1-foot-4-inch cantilever—over a dropped beam to build the same-size deck. This option saves on lumber and metal-connector costs.

Joist spans for a 10-foot-wide-by-16-foot-long deck. For the 10-foot-by-16-foot deck shown in the plan and section views below, 2×8 southern-pine joists at 16 inches on-center are “oversized” per IRC Table R507.6 (above).

Using a dropped beam (above right) instead of a flush beam (above left) reduces the 10-foot joist span to 8 feet 8 inches with a 1-foot-4-inch cantilever, allowing the joists to be downsized to 2x6s at 16 inches on-center.

Cantilevering the Beams

Per Table R507.5 (below), the IRC beam design provisions allow beams to cantilever an additional one-fourth the span beyond the last post. Utilizing this allowable cantilever is a wise way to have more deck supported on the same beam, without additional support posts. Additional posts not only drive up costs, but they also inhibit views from beneath an upper-level deck.

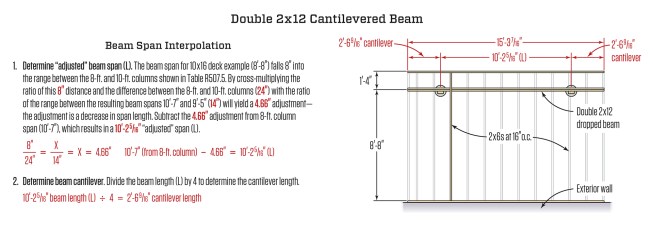

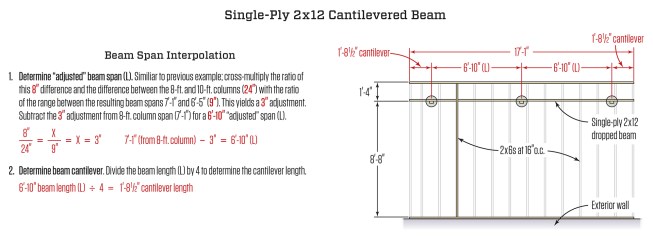

Lesson: One way to support a 10-foot-by-16-foot deck is with a double 2×10 beam bearing on three posts. By upsizing to a double 2×12 beam, dropping the beam, and taking advantage of the IRC’s L/4 beam cantilever provision, as shown below, only two posts would be required to support the deck framing. Making use of beam cantilevers allows you to size smaller and less costly beams, as well as minimizing the number of posts.

Determining beam span. Table R507.5 (above) includes a footnote (g) that provides for an additional cantilever equal to the beam’s listed span divided by 4. On a 10-foot-by-16-foot deck, upsizing to a double 2×12 dropped southern-pine beam and using this cantilever provision reduces the number of posts needed from three to two (though the deck’s length will be slightly reduced).

To interpolate spans not shown in the table, use the ratio shown above to find the “adjusted” span.

Using Single-Ply Beams

The 2018 IRC expanded the deck-beam span table to include single-ply beams. Table R507.5 “Deck Beam Span Lengths” has five new rows for 2×6 through 2×12 single-ply beams. The spans aren’t huge, but they help the IRC be what it is supposed to be—a minimum standard. In many designs with short beam spans or short joist spans, a single ply is sufficient as a beam. A stronger beam can carry more load, but the load it carries comes from the joists. Unless the joists are also oversized, they become the load limit. There is no benefit to blindly building beams that are twice as large and expensive. As shown in the table below, a single 2×10 beam can span 6 feet while carrying 2x8s spanning 8 feet and cantilevering another 2 feet.

Lesson: When beam spans are less than 8 feet, you may be able to use a single-ply beam. A single-ply beam will have much better decay resistance, as there is no space between members to trap moisture. A single-ply beam also allows for the connection of a 4×4 support post with a notch and bolts in place of a post cap connector. In addition, a single-ply beam allows for outside mounted guard posts to connect back into the deck frame with fewer intermediate members inside the connection. Single-ply beams can provide a design advantage, while also reducing costs.

Single-ply beam. The IRC’s beam span table includes sizing for single-ply beams, showing that a single 2×12 beam can be used to support a 10-by-16-foot deck.

Although the beam will require three support posts, the single-ply beam can cantilever, allowing the deck to be widened to 17 feet, as shown in the plan view above. To interpolate the spans shown in Table R507.5 to determine the “adjusted” span of the single-ply 2×12 dropped beam, use the ratio shown above.

Dropping the Deck

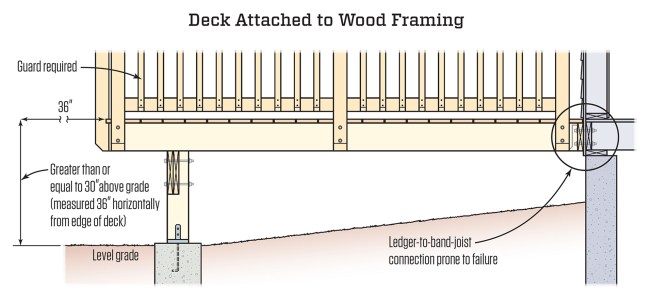

The past decade of deck building has seen an increasing focus on the ledger connection, and rightfully so. Many decks insufficiently attached to wood framing or attached to decayed material have been collapsing. However, if you examine this subject closer, you find that all the failures are due to a connection to wood framing.

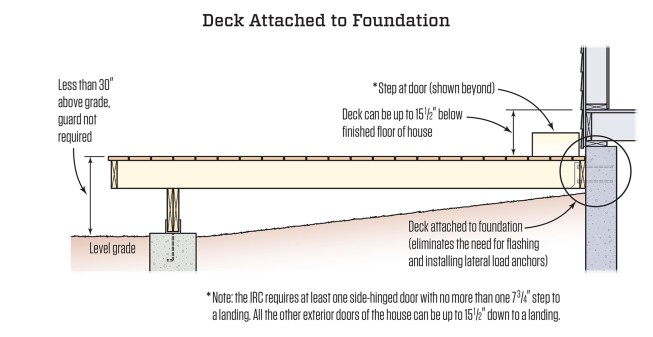

On a first-floor deck, an advantageous design is to drop the deck below the wood framing and attach it directly to the foundation. This changes things—big time. All the concerns that drive the misunderstanding of the IRC’s lateral-load-anchor details disappear. Take away the connection to the band joist and you eliminate the weakest link in the chain. In structurally sound concrete, common 1/2-inch-diameter mechanical or adhesive bolt connections of the ledger to a concrete foundation are more than sufficient for most common deck designs.

-

Deck and Railing Skills Workbook

No one can afford a deck failure. Focus your crews on safe and durable deck building with JLC’s Deck and Railing Skills Workbook.

The lateral-load anchor isn’t the only thing to disappear, as flashing is no longer required. The IRC requires deck ledgers to be preservative treated, and flashing is required only when attaching to wood framing. Ledger flashing is primarily meant to protect the house framing, not the ledger. With a connection to the foundation, the exterior cladding and water-resistive barrier is not penetrated (another benefit to dropping the deck), and thus there is no counterflashing to place ledger flashing behind.

Though not directed by code, it may be useful to run a bead of sealant down the top of the ledger at the foundation, or better yet, space the ledger 1/2 inch off the foundation for drainage and drying behind.

Lesson: For first-floor decks, drop the deck below the framing and attach it instead to the foundation. This eliminates damage to the cladding, as well as the need to install flashing and lateral-load anchors. Unless there is a side-hinged door, the deck can be up to 15 1/2 inches below the house framing, with the construction of a single step. Otherwise, a small landing can be built outside of the door. First-floor decks are also often close enough (30 inches or less) to ground level that guards may not be required.

A deck that is hung from a ledger fastened to the rim joist requires ledger flashing to protect the house framing and often requires lateral-load hardware. In addition, decks that are more than 30 inches above grade around the perimeter of the deck require guards, adding to the cost of the deck (above).

Anchoring the deck to a sound concrete foundation eliminates the need for ledger flashing and lateral-load anchors. This approach also allows the deck to be dropped closer to grade, eliminating the need for guards.

Taking Advantage of Foundation Exceptions

For ground-level decks, the IRC offers a few options for relief from robust foundation systems. The simplest is allowing joists to bear directly on the ground (see IRC R507.3, exception). In this construction, they aren’t really joists, in the sense that they don’t span between bearing points. If the joists are preservative treated for ground contact and fully supported along their bottom edge on grade, then I don’t expect to see any concrete delivered. For decks up to 20 inches above grade, the joists can be independently supported by pier blocks bearing on grade, rather than by beams and ledgers. Neither of these construction methods would be suitable for supporting guards around the deck, but their limited height above grade is meant to avoid that necessity.

Lesson: When a deck is built at ground level, there’s nothing wrong with it structurally functioning as flagstone or patio pavers would function. There is little hazard in the structure of wood sitting directly on the ground.

A grade-level deck doesn’t need to be supported by a concrete foundation, as long as the deck is not connected to the house framing.

Using Less Concrete

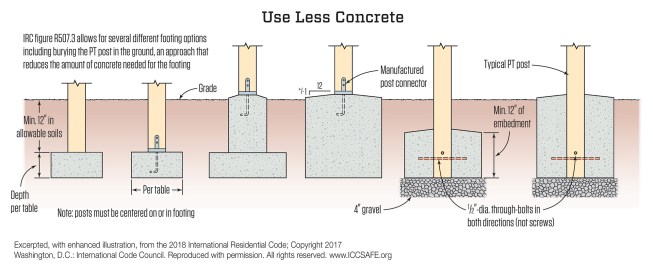

There are two ways to use less concrete in your deck footings: Leave it all at the bottom or bring it all up to the top. When preservative-treated posts rated for ground contact are used, the IRC allows deck support posts to be sunk into the ground. For areas with a frost depth and thus deep footings, there is no requirement that the concrete come up to the surface. A minimum 6-inch-thick concrete footing can in most cases be poured at the bottom of the hole and the post placed directly on top without a post base.

However, this is permitted only when the soil type is sufficient for lateral restraint and the post is embedded at least 12 inches into the earth. This is not acceptable for conditions where uplift design is required or when posts support a roof above the deck. In regions with a 3-foot frost depth, this strategy can result in huge savings in concrete and labor, not to mention the cost for post-base hardware.

The other option is frost-protection exceptions. If a deck is not supported by another frost-protected structure (like a ledger connection to a house), then the footings are not required to be frost protected. Freestanding decks can save in concrete and excavation expenses in exchange for no frost protection. Bear in mind that some regions have soil and groundwater sufficient to create problems with frost heave that may make this code-compliant choice a poor consumer choice. However, in other freezing regions, the soil is not conducive to frost heave and using this exception will likely make no difference in performance.

Lesson: The only concrete that matters in a deck footing is the concrete in contact with the soil. The IRC provides many options to consider for minimizing the amount of that concrete.

IRC Figure R507.3 specifies connection details between deck posts and deck footings. It also provides for different deck foundation options, including posts that are buried in the ground to reduce the amount of concrete needed for the footing.

Photos by Glenn Mathewson