Even as our deck projects continue to grow in size and complexity, we find that we’re always learning something new on every job. Recently, for example, we discovered how useful ice – yes, frozen water – can be when installing a large swim spa. Let me explain.

The spa was a late addition to what was already a fairly complex project, the makeover of a hillside deck into a multi-level structure with a total of more than 1,500 square feet of outdoor living space. Our clients liked the idea of a small pool-style spa, and asked us to research the advantages and disadvantages of site-built vs. prefabricated self-contained units.

After looking at factors such as cost, features, and energy consumption, my clients chose a Hydropool AquaTrainer 17fX, which was supplied by Aqua Quip, a Seattle-area company that specializes in hot tubs and spas. Measuring about 8 feet wide by 17 feet long, the fiberglass unit features both swim and hydrotherapy jets, built-in pumps and heaters, and LED lighting. The size and weight of the unit – almost 3,000 pounds empty and more than 21,000 pounds when full – required careful planning, especially considering the hillside location of the spa.

Concrete work

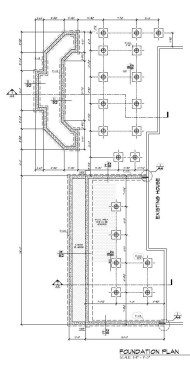

The deck design – by The Leren Company of Mill Creek, Wash. – is anchored by a pair of massive concrete retaining walls. Because of the sloped site and the project’s location in a Class D (high risk) seismic area, we consulted with a geotechnical engineer to assess the stability of the soil and review the foundation plan prior to excavation.

The foundation plan showing the location of deck piers and the layout for the deck's footings and foundation walls.

The retaining wall that partly supports the deck framing surrounding the spa is part of a large earth planter that forms the outer edge of the lower deck. To support this retaining wall/planter assembly, we formed and poured a 14-inch-thick by 5-foot-wide by 34-foot- long steel-reinforced concrete footing, along with another similar-sized but more irregularly shaped footing for the multilevel portion of the project. We also formed and poured narrower footings for the remaining stem walls and for 15 of the piers that would support the deck structure. Then we formed the walls and set our sonotubes for the piers, also reinforcing the piers with #4 rebar.

Both the inner and outer walls of the earth planter/retaining wall assembly – required to stabilize the sloped site – are supported by a steel-reinforced spread footing.

Here the retaining walls have been formed and are ready to be filled with concrete.

After stripping the forms off the retaining walls, we formed and poured the 7-inch-thick reinforced concrete slab that supports the spa. Where support posts for the deck framing that surrounds the spa would bear on the slab, we excavated an additional 16 inches below the slab for the eight footings. We reinforced both the slab and the footings with #4 rebar, which was tied together to create an interlocking pattern. We also used rebar to pin the slab to the retaining wall.

A reinforced slab was needed to support the large spa, which weighs over 21,000 pounds when full. Note the excavations for additional footings to support the piers that will also bear on the slab.

Crew members fill the piers with concrete from the pumper truck, prior to pouring the spa slab.

During the project, we pumped nearly 44 yards of concrete to form the footings, retaining walls, slabs, and piers necessary to support the deck framing on the sloped site.

Setting the spa

Once the concrete cured, we got to work installing the 6×6 PT support posts and deck framing. While waiting for delivery of the spa, we completed the upper deck using Trex’s Tiki Torch decking in the field and Lava Rock for the picture frame, borders, and stair returns. To provide for dry storage, we installed Trex’s RainEscapes underdeck drainage system.

Since the spa bears on the slab rather than the framing, the deck was built with standard PT lumber and deck details.

Because of the size of the unit and the difficult hillside location, we contracted with a crane company to set the spa. A 90-ton crane was needed to pluck the spa off the flat bed delivery truck, hoist it up over the roof of the house, and gently lower it more than 60 feet down into position. Making this even trickier, there was less than one inch of clearance between the sides of the spa and the framing.

Here the spa is being lowered into position with the help of a 90-ton crane. The upper deck was fitted with an underdeck drainage system beneath to provide dry storage for covers, cushions, and deck furniture.

Here’s where the ice trick came into play. Normally, when setting a 3,000-pound spa onto a slab with tight framing surrounding it, blocking is used to support the unit while pulling out the crane straps. But we’ve found that this method sometimes results in damage, so on this project we supported the spa with six bags of ice, one on each of the corners and one at the midpoint on each of the long sides of the spa, located so that the ice was out of the way of the lifting straps. The technique was recommended to us by the trucking company that delivered the spa, and we were able to easily remove the lifting straps once the spa was in position and supported by the ice. As the ice melted, the unit slowly settled into place with minimal adjustments needed.

The spa is equipped with a reinforced removable cover that can be stored away when the spa is being frequently used, as well as a summer bubble cover that is easy to slip on or off.

Because of the design of the earth planter, the 48-inch-high security railing required by code around the spa is dropped 24 inches to take advantage of the great view of the Puget Sound waters.

With the spa installed and the plumbing and electrical connections made, we completed the lower deck and installed the Fortress vertical cable railing system. The design features a set of stairs connecting the lower spa pool deck to the upper deck where the gas fire pit is located. To meet local code, each gate into the spa area has a safety alarm, and the spa is completely enclosed around the perimeter with an aluminum railing fabricated by American Structures and Design.

Along with the spa, the project includes multiple areas for relaxation and entertaining.

Washington state code requires at least a 48-inch-high guard fence around swim structures. But because of the design of the earth planter, which creates a 36-inch-wide level area that is less than 30 inches below the front edge of the deck, we were able to drop the elevation of the guard fence without reducing its overall height. This provides our clients uninterrupted views of nearby Puget Sound while they enjoy their hillside spa

.