Informal Solutions

Because my engineer is known for being very conservative, some of the building inspectors we work with will accept scaled-down and unstamped versions of his engineered brackets and braces.

Simple diagonal brace. In the “lite” version of our diagonal foundation brace, we’ve substituted joist hangers or pairs of 16-gauge angle brackets for the more robust—and more expensive—3/8-inch and 1/4-inch steel L-brackets used in our stamped designs. This detail can be built with either a single or a double 2×8 diagonal brace, which is through-bolted to a doubled deck joist and anchored to the concrete foundation as shown. Materials cost about $32 for each brace, and it takes about 45 minutes to install one of them.

While we’ve had two or three inspectors accept this brace as “reasonable” without asking to see any engineering data, the weak link in the design is the metal hardware. We typically use Simpson LUS28-2 double-joist hangers—which have a 1,315-pound allowable load capacity—or Simpson L70 angle brackets, which have a load capacity of 445 pounds each (for a total capacity of 890 pounds for a pair of brackets) in treated lumber, though the load capacity may need to be reduced since the brace is configured diagonally. If a lateral load requirement of, say, 750 pounds is added to future versions of the building code, this alternative configuration using off-the-shelf hardware would probably meet that lower standard.

House-frame bracket. On older homes with fieldstone foundations, lateral braces can’t be fastened to the foundation. But on a recent project—a classic New England house with solid 4×6 sills—the inspector suggested I anchor our custom L-bracket lateral braces to the sill.

Bad Solution to a Non-Existent Problem?

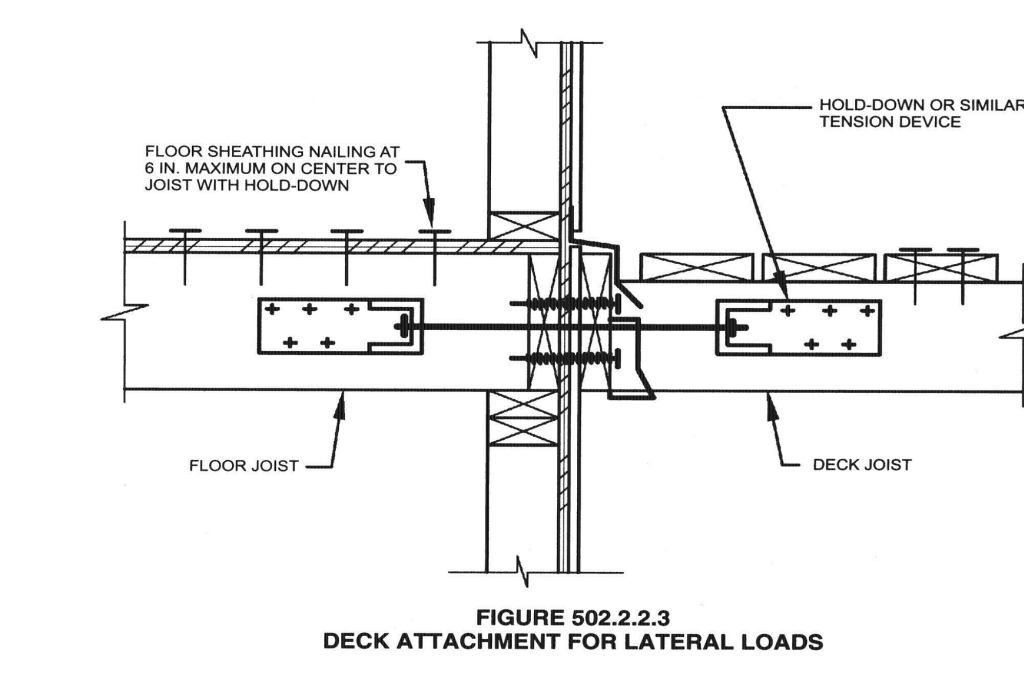

The reason I developed the alternative lateral braces described in this article is that installing the code-permitted device is disruptive and complex, especially when house joists are perpendicular to deck joists. Because it requires the house subfloor to be attached to the joists with nails 6 inches on-center (rather than the standard 12 inches on-center), the finished floor would have to be removed in order to verify that or remediate it. But the biggest problem for me is that the deck has to be level with the house floor in order to install the device, a bad practice where rain and snow is common.

Often overlooked in discussions about lateral loads is that the lag bolts and ledger screws used to transfer a deck’s vertical load to the house also resist withdrawal forces: 582 pounds for each 1/2-inch-diameter lag bolt, and 420 pounds for each LedgerLOK screw embedded 2 inches into an SPF house-framing member. This means that a 16-foot-wide deck with two ledger screws per 16-inch joist bay would have more than 10,000 pounds of lateral resistance.

One explanation I’ve heard for the lateral-load connection requirement is that it prevents a deck from pulling the band joist or sill away from the house under a severe lateral load. But I’ve never heard of this actually occurring, except when the deck ledger has been fastened to an overhanging cantilever. And in those cases, the issue is vertical rather than lateral loads.

Recent testing at Washington State University confirms this. There, people moving in unison on a sample deck were able to create a maximum total lateral load of only 1,750 pounds—875 pounds at each end of the deck. Even under artificially-created lateral loads of 7,000 pounds, the joists split and failed massively but the lag screws at the ledger held firm—without any lateral braces. There was no observed damage to the house frame (see the online series Lateral Loads on Decks by Don Bender et al., originally published in Wood Design Focus (Summer 2013) and reprinted with permission.

This testing suggests that real-world lateral loads are relatively small, and shows that even artificially created loads that are four times real-world scenarios are easily handled by standard deck attachments that follow IRC connection requirements. Hopefully, common sense and recent tests of actual lateral loads on decks will result in a modification of future building code requirements—and perhaps even eliminate the “permitted” device drawing.

I rotated the brackets so that they were oriented horizontally instead of vertically, and drilled another hole through each bracket for a third through-bolt. After flashing the brackets with Vycor, I fastened each one to doubled 2×10 PT joists with three 1/2-inch-diameter galvanized-steel through-bolts. The brackets are anchored through the deck ledger and house sheathing into the sill with six 6-inch HeadLOK screws per bracket.

Is this anchor strong enough? According to my calculations, each of the three through-bolts holding my bracket to the double joist will resist 620 pounds of shear—more than 1,800 pounds total. According to the screw manufacturer’s ESR (Evaluation Services Report 1078), the withdrawal strength of a HeadLOK screw embedded 2 inches into a hem-fir sill is 360 pounds; therefore, six such screws should resist 2,160 pounds of withdrawal (6 x 360 = 2,160).

Including the bracket and the second joist, materials for this detail cost about $48. Installation takes about 30 minutes.

Faster and Cheaper

Both the engineered and “informal” devices I’ve described in this article have several major advantages over the lateral brace “permitted” by the IRC. Installation is easier and less expensive, since my details require no access to the interior flooring, basement ceiling, or floor joists. And they allow us to set our decks 6 or 7 inches below the interior house floor, a practical detail that helps keep rain and snow outside.

Are all my lateral anchors as strong as the code-permitted solution, which depends on special hardware, extends deep into the house, and attaches to the floor framing? Some of them are and some of them aren’t, but I’m not too worried that my decks would experience an arbitrary 1,500-pound lateral force on the ledger that would pull the rim joist or sill away from the framing, through the house sheathing, and onto the ground.

Jim Finlay is the construction manager and owner of Archadeck of Suburban Boston, a member of the Archadeck franchise system.