David Michalak

ThruLok bolts drive through the wood members with no pre-drillin…

Ledger to House

In recent years, there have been more code changes, confusion, and regulation pertaining to how a ledger is attached to a house than in any other area of deck building. And with good reason — ledger pull-out due to gravitational and lateral forces is a major reason decks collapse.

In the past the only options for attaching a deck ledger to the house were 1/2-inch lag bolts or 1/2-inch machine bolts. Proper installation of lag bolts requires drilling two different-sized holes — a smaller one for the threaded portion of the bolt and a larger one for the bolt’s unthreaded shaft. Through-bolts require access from inside the house, which may not exist. Now, a fast alternative to a lag or a through-bolt is available: a self-drilling ledger screw. It requires no predrilling, and is usually installed with an impact driver. FastenMaster, GRK, and Simpson all make ledger screws, which cost approximately 50 cents each, depending on their length and material.

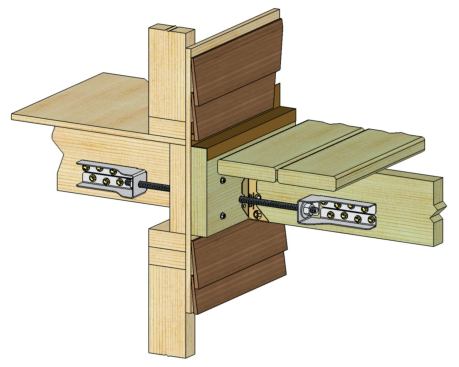

FastenMaster’s ThruLok bolts are a speedy alternative to through-bolting at ledgers, posts, and girders. They have a wing nut that spins onto the point of a self-drilling screw. Drive the screw through the members you’re fastening, then thread the nut on hand-tight. Tighten the screw with an impact driver, and spurs on the nut grip the wood as the fastener tightens — no wrench needed. ThruLok bolts cost about $2 each, depending on length.

Don’t think you can zip in a few handfuls of ledger screws and satisfy your building inspector, however. According to Rhode Island builder and frequent PDB contributor Mike Guertin, “Between the downturn in new construction and the attention decks have gotten in the news (we had two collapses in Rhode Island in the past year that the media picked up) and the code revisions, building officials are becoming deck-hawks.” And changes to the 2012 building code have strict requirements about the spacing and locations of these fasteners as they pertain to the structure of the existing house (Structure, May/June 2012).

If your jurisdiction has adopted the lateral attachment details in the 2009 and 2012 IRC, you’ll need more than just bolts or screws to attach the ledger to the house. Unless you have an engineered solution that your building department will sign off on, combatting the lateral forces that a deck is subjected to requires special brackets that bolt through the ledger and band joist to mechanically attach the deck joists to the house’s floor joists.

None are simple to install and all require access to the house’s floor-joist system — not fun if you’ve got a finished floor and ceiling to deal with. Simpson’s bracket, the DTT2, takes a 1/2-inch-diameter machine bolt and USP’s DTB-TZ bracket can take a bolt or threaded rod. For these brackets, the manufacturer’s details show the house and floor joists in line with each other. There are alternative details that allow these brackets to work when the ledger is parallel to the joists, but it’s up to the local building inspector whether or not to accept that installation (Structure, January/February 2012).

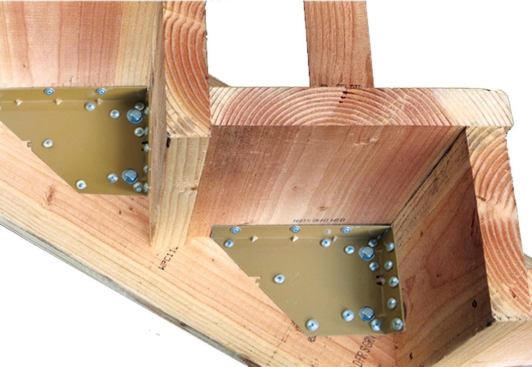

A bracket made by DeckLok can also be used to provide lateral support. Two DeckLok brackets are needed at each lateral-support location. One bracket through-bolts to the deck joists and through the deck ledger and band joist. A second bracket through-bolts to the house joist and through the band joist and ledger, locking all members together. One advantage is that the house and floor joists can be offset. A disadvantage is cost: Compared with Simpson and USP brackets that cost approximately $11 a pair, DeckLok brackets cost $22 a pair (or $44 a pair for stainless). None of the manufacturers include the necessary machine bolts or threaded rod with the brackets.

Sources of Supply

DeckLok

877/844-8880

deck-lok.com

EZ Stairs

866/693-9570

ez-stairs.com

FastenMaster

800/518-3569

FastenMaster.com

GRK

800/263-0463

grkfasteners.com

Phoenix Metal Products

516/546-4200

phoenixmetalproducts.com

Simpson Strong-Tie

800/999-5099

strongtie.com

USP

800/328-5934

uspconnectors.com

Simpson Strong-Tie and USP are the two major manufacturers of framing hardware. Their product lines are very similar; which one you buy depends in large part on what’s stocked at your lumberyard. Phoenix Metal Products is a family-owned metal fabricator that makes many of the same connectors as Simpson and USP at its Freeport, N.Y., plant. In fact, Phoenix publishes a chart that cross-references its connectors with Simpson’s and USP’s at framingconnectors.com. Andy Wolf, vice president at Phoenix, says that most of its customers are production builders that buy connectors in large quantities. “But if you need a custom connector that you can’t find anywhere else,” he says, “our turnaround time is very fast, which is an advantage of dealing with a smaller company.”

Stairs to Framing

Not surprisingly, there is also structural hardware to attach stair stringers to deck framing. (The code prohibits toenails or “nails subject to withdrawal.”) Simpson’s adjustable LSC brackets get fastened to the framing and then bent onto and fastened to the bottom and sides of the stringers. Left- and right-hand brackets are available so that the hardware is concealed to the inside of the stringer. USP’s stringer bracket, CSH-TZ, is similar but reversible, so “handed” versions are not necessary for concealment. Adjustable stringer brackets cost about $5 each.

DeckLok brackets can also be used to secure stringers to framing. These brackets have one bolt hole on one leg of their L-shape and two on the other leg. The company’s president, Jim Miller, says, “It’s important to remember that the two-hole leg of the bracket always gets fastened to the floor joist or stringer — whatever member would be most subject to withdrawal. The one-hole side of the bracket gets bolted to the rim joist or ledger.”

Post to Framing

It’s easy to understand why people worry about railing-post failures. If you wanted to pry apart a deck frame, you’d probably use something long with a lot of leverage — like a typical railing post.

Hardware can help offset the leveraging power of the post by transferring it to the floor-joist system. Simpson, USP, and DeckLok lateral support brackets can be used for post-to-framing connections (“Code-Compliant Railing Posts,” May/June 2011).

EZ Stairs makes bracket sets that take the guesswork out of building stair stringers (Decking News, March/April 2008). A single EZ Stairs bracket can be used to make a strong, code-compliant (according to the company’s website) post-to-stringer connection on a set of stairs.

To use the bracket, sandwich the stringer between post and bracket with two through-bolts. The post gets its ultimate strength from the bracket being screwed both to the blocking between the stringers and to the stair treads. A pair of EZ Stairs brackets (enough for two posts) costs about $13, fasteners not included.

For the past six years, at DeckExpo and elsewhere, Mike Guertin has run many post-to-frame-connection workshops, which he says are “always packed.” It’s a complex topic, full of confusion and false claims. Guertin says, “No piece of hardware or proprietary design is ‘code approved.’ Only things specifically called out in a code book are code approved. It is entirely up to the local building official to accept alternative construction details on a case-by-case basis. But one official’s acceptance is not precedent-setting nor does acceptance as an alternative rise to the level of code approved.”

Bottom line: Talk to your building department before you fill your shopping cart with brackets, bolts, screws, and washers.

Former carpenter Jefferson Kolle is a freelance writer in Bethel, Conn.