Cramer Silkworth

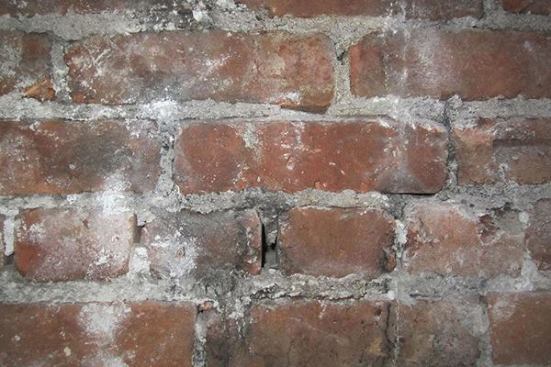

Before: the existing brick party walls are more than 100 years o… Before: the existing brick party walls are more than 100 years old. They need to be repointed and patched in places, then given a parge of lime-based mortar that matches the existing historic material.

Cramer Silkworth

Here, a section of brick party wall has been partly covered with… Here, a section of brick party wall has been partly covered with a parge of wet lime mortar slurry, and partially coated with a water-repellent and air-tight, but vapor-open, coating of Sto Emerald Cote. The entire wall will be parged and coated to create a continuous “air control layer” between the occupied space and neighboring buildings or the outdoors.

Cramer Silkworth

A worker applies Sto Emerald Cote to a masonry wall as part of t… A worker applies Sto Emerald Cote to a masonry wall as part of the remodel of a Brooklyn brick row house. The Sto Cote is vapor open, but air tight, says Passive House consultant Cramer Silkworth.

Jose Maldonado

Jose Maldonado’s framing crew studs up the wall inside the str… Jose Maldonado’s framing crew studs up the wall inside the structural brick front of the Brooklyn row house. This wall will be covered with ProClima Intello smart vapor retarder as part of a continuous vapor control layer that includes the front wall, the rear wall, and the ceiling of the home’s top story. The front wall receives five to seven inches of cellulose — the least heavily insulated plane of the building envelope, except for the party walls shared with neighboring units (which are in contact with conditioned occupied space).

Jose Maldonado

A view of the existing roof framing of the hundred-year-old Broo… A view of the existing roof framing of the hundred-year-old Brooklyn row house, including modifications implemented as part of the current project. The building’s floor and roof framing has been reinforced in places with LVL, steel, or parallam members, and visible in this view is solid blocking installed between roof joists as nailing for the ProClima Intello smart vapor control membrane and for ceiling drywall. Blocking is caulked to the ceiling framing and the wall in order to help maintain a robust air barrier, or “air control layer.”

Nate Dorr

Here, the roof framing overhead has been covered with ProClima I… Here, the roof framing overhead has been covered with ProClima Intello smart vapor control membrane, and workers are taping the seams in the membrane using ProClima Tescon Vana tape. The membrane is also being taped to the Sto Emerald Cote surface of the brick party wall. The long brick wall divides the residence from the conditioned space of an adjoining neighbor, and therefore does not have to be insulated.

Nate Dorr

A carpenter applies ProClima Tescon Vana tape to the Intello sma… A carpenter applies ProClima Tescon Vana tape to the Intello smart vapor control membrane along the line of the framing member. Passive House consultant Cramer Silkworth explains: “Generally, you don't have to tape over the fasteners for air-tightness. In this case, after tacking the Intello in place, the guys are taping the staple path first, then stapling through both the tape and the Intello to reinforce it there, but only as an extra precaution. Often, we apply cross-strapping to a ceiling before applying drywall, to form a service cavity for wiring, and that would help hold the cellulose up. But in this case, we have a lower ceiling, so we just want a bit of insurance.”

Nate Dorr

A worker carefully tapes the ProClima Intello membrane to the br… A worker carefully tapes the ProClima Intello membrane to the brick party wall, which has been parged with mortar and coated with Sto Emerald Cote. When the Intello is fully installed and taped to the brick, the dwelling’s occupied space will be fully enclosed within an air control layer consisting of the Intello membrane on the front wall, ceiling, and back wall, and the sealed brick party walls on either side.