Air conditioning systems have a two-fold task: controlling temperature and moderating humidity. As codes increasingly require forced mechanical fresh-air ventilation in houses, the second job is gaining in importance. That’s because in most parts of the United States, and particularly in central and southern regions, outdoor air carries a lot of humidity with it as it enters the house. JLC looked at that issue in this space in May 2018 (“Controlling Humidity in Warm Climates”). This month, we’re back for a second look. At the Humid Climate Conference in Austin, Texas, in May, a two-hour presentation by building-science consultant Lew Harriman of Mason-Grant (masongrant.com) went to the heart of the humidity-control topic. With several case examples and an insightful summary of technical issues and approaches, Harriman shed new light on the theory and practice of managing humidity in homes—insight we’re putting forward in advance of systems you might be designing for or installing next year.

Moist Mansion Mystery

Harriman’s first example was a troubleshooting case involving a puzzling moisture problem in a brand-new custom home in the Chicago area, owned by a wealthy businessman. With four finished floors from basement to attic, this house was well insulated and impressively airtight, and it was equipped with advanced air conditioning, exhaust ventilation, and an energy recovery ventilator (ERV). It should have been a good performer. But there was a problem with indoor humidity: Night and day, season in and season out, the house ran relative humidities in the high fifties and above.

Harriman was called in for a diagnosis. An initial review turned up none of the usual suspects, Harriman recounts: “What’s the load? Are they taking lots of showers? Nope. Are they breathing heavily at night? No, this is happening during the day. Are they scrubbing a herd of puppy dogs in the bedroom at night? No. Do they have lots of plants? No. There’s nothing in this house that suggests that there is a big internal humidity load. Nothing.”

Conference attendees suggested other possibilities, and one by one, Harriman shot the ideas down. Wet basement? Nope: “Bone dry. Beautifully drained, beautifully waterproofed, nice capillary break under the slab.” Blocked condensate drains? Good thought, but no: “They had lovely big traps that you could clean out, and a couple of them were transparent, just the way they should be so that you could see whether they were clogged, and they were new.” Cooking moisture? The owner’s professional chef ran the huge exhaust fans every day as he prepared family meals.

The building’s hired manager provided a major clue. Says Harriman, “He took the metal panel off the side of the ERV and replaced it with Plexiglas.” Then he hung a small strip of light plastic inside the ERV, next to the exhaust port. The manager’s cellphone video of this rigged-up wind gauge clearly told the tale: Whenever too many of the home’s many exhaust fans (which included two commercial dryer vents, lots of bathroom vents, and a huge kitchen exhaust fan) were running, the strip of plastic bellied inward. Rather than functioning as a balanced air exchanger, the ERV had become a straight air intake port. Overwhelmed by the building’s powerful exhaust fans, both legs of the machine were drawing in humid outdoor air. Under worst-case conditions, with all the exhaust fans running, Harriman measured 27 pascals of negative pressure—and that’s in a house with four fireplace chimneys.

As far as he knows, Harriman says, this house was never fixed. Any proposed solution bogged down in disputes over who was responsible. But Harriman says that the first place he’d look for answers would be the range hood, which, at 948 cubic feet per minute (cfm) of actual measured airflow, was much more powerful than it needed to be. Equipment sizing was a factor as well. A Manual J calculation performed after the fact by consultant Corbett Lunsford indicated that the home needed 7 tons of cooling under design conditions; the builder had installed 11 tons.

Even in an ideal world, notes Harriman, Manual J sizing guidelines use a peak cooling load that would be exceeded for only 36 hours in a typical year. “That means that all mechanical equipment is oversized for 99.6% of its operating hours,” Harriman comments. And while oversized equipment may dominate the cooling load, it struggles to control humidity, because moisture that condenses on the coil tends to re-evaporate into the house as soon as the short cooling cycle ends.

So this house didn’t have the equipment it needed. The ERV controls humidity only if it’s actually exchanging air, and then only if the indoor air is already dry. The cooling equipment dehumidifies only if it’s running—which, for 99% of the year, is only part of the time. What was missing was a full-time dedicated dehumidifier, set to respond to excessive humidity, not to high temperature. And that dehumidifier, as Harriman would explain, should be arranged to dehumidify outdoor air as it enters the building.

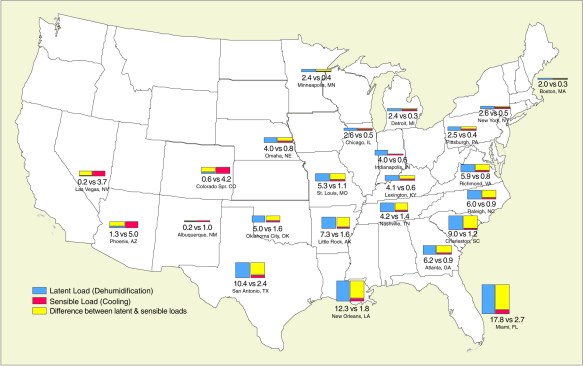

The graphic above depicts the relationship between the sensible (cooling) load and the latent (dehumidification) load in various locations in the United States. Very commonly, air conditioning systems have to deal with a latent load that far surpasses the sensible load.

Desert Monsoon

Harriman’s next example cast an even sharper light on the humidity problem posed by incoming air. The case comes from early in Harriman’s career, when he was a commercial market manager for a dehumidifier supplier. A call came in late on a Friday from a semiconductor manufacturer in Arizona: “We need some dehumidifiers by Monday.”

A humidity problem in Arizona? Yes. Most of the year, Arizona has desert conditions. But for a brief period from July to September, that part of the Southwest gets something called the “Arizona Monsoon,” a season of high humidity and frequent thunderstorms, fueled by moist air coming up from the Gulf of Mexico and the Sea of Cortez.

When he analyzed the chip fab plant’s numbers, Harriman saw the pattern that would grow familiar to him over his long career: The indoor sources of humidity were modest, and were dwarfed by the humidity brought in by ventilation air. “So if you were the designer,” asked Harriman, “where would you put the dehumidifier? Me, I would put it on the ventilation air.”

Harriman equipped the factory’s intake ports with desiccant dehumidifiers and moisture-responsive controls. Once that was accomplished, the humidity spikes and dips went away, and the humidity remained stable around the clock, month in and month out.

In the commercial and industrial world, Harriman says, drying the ventilation air is a lesson learned long ago. But in residential construction, moisture problems are still treated as a mystery. Equipment is oversized, focused on cooling, and controlled to respond primarily to temperature rather than the moisture load.

A city-by-city list of major American locations shows how the work done by air conditioners is commonly dominated by the requirement to remove humidity from the air.

Florida Flow Meter

Harriman’s third case didn’t directly involve ventilation air. Instead, it was an investigation of indoor mold complaints for a development of homes near Tampa, Fla. Mold was growing on ceilings, primarily in second-floor mechanical rooms, and the assignment was to find out where the moisture was coming from.

In the end, Harriman and colleague Andy Ask concluded that the source of moisture was a humid vented attic. Daily temperature cycles were letting the attic fill with hot, damp air, and heat was driving the moisture through ceilings into the home. But what’s interesting in this case is that Ask and Harriman were able to put hard numbers to the amount of moisture the home’s air conditioners and dehumidifier were extracting from the home’s indoor air.

They did this with a simple method: They measured the condensate. They positioned a tipping bucket rain gauge where it could catch condensate dripping from the home’s air conditioners and dehumidifier, and they counted the times the bucket tipped with an electronic “pulse counter.”

In this case, the air conditioners were able to do the bulk of the work. Over the course of 13 days in August and September, one air conditioner pulled out 492 pounds of water, and the other pulled out 290 pounds; the dedicated dehumidifier removed an additional 300 pounds of water. These homes, interestingly, didn’t have any powered fresh-air ventilation at all. So for purposes of comparison, Harriman calculated the amount of moisture the HVAC systems would have had to contend with if the houses did have incoming fresh air as recommended by ASHRAE Standard 62.2. The result is eye-opening: If the homes had been ventilated that heavily, the moisture load would have roughly tripled.

Lew Harriman and colleagues devised the system shown above to measure the water output of a house air conditioning and dehumidification system. Water emitted by the building’s condensate drain filled a bucket, which tipped over when full.

A pulse counter counted the bucket tips, keeping a running total of the drain’s performance.

The Takeaway

To avoid moisture problems in homes, Harriman concludes, builders need to realize that the humidity contained in outside air is the big gorilla in the room. To drive home the point, Harriman quotes from a senior colleague, Don Gatley, author of the book Understanding Psychrometrics. “Don Gatley did 79 moisture investigations in his career,” says Harriman, “and he told me that all but four were caused by either too much building suction or not enough drying of the ventilation air.”

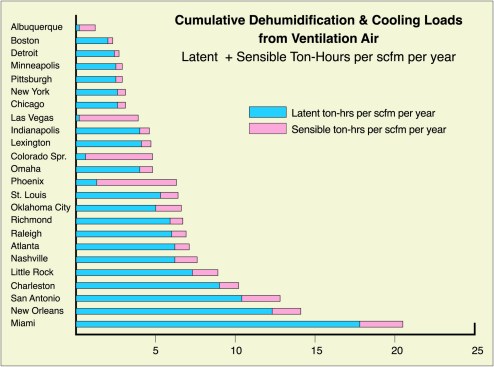

More than 20 years ago, Harriman and some colleagues published a paper about the moisture contained in ventilation air. Analyzing more than 200 data sets from locations around the nation, they concluded that the humidity load of incoming air exceeds the sensible cooling load of the air almost everywhere. The authors proposed a new unit, the “ton-hour,” to compare the annual loads associated with ventilation (the unit would equal a ton of cooling capacity, operating for an hour).

In some cases, the loads are extreme. In Miami, for instance, every cfm of continuous ventilation will require 17.8 ton-hours per year for dehumidification, versus just 2.7 ton-hours for sensible cooling. In milder climates, the total loads are lower, but the ratios are similar. Boston, for example, with 2.0 ton-hours of dehumidification and 0.3 ton-hours of sensible cooling, needs less energy overall to treat incoming air, but the ratio between dehumidification and cooling is about the same as in Miami.

To sum up, Harriman offered a number of lessons:

- Don’t oversize cooling equipment.

- Install dedicated dehumidification.

- Dry out humid ventilation air before it gets indoors.

So while we often think of wet basements as the biggest cause of indoor moisture, and we think of kitchen and bath vents as the best way to remove intermittent humidity, those are just the starting points when the code requires continuous ventilation. When continuous ventilation is required, reliable humidity control requires a dedicated dehumidifier. Harriman recommends placing that dehumidifier so that it dries out the incoming air before it gets into the house. Keeping excessive humidity out of materials provides the dry indoor environment that meets owners’ expectations: a house that is comfortable, well ventilated, and mold-free.

Photos and graphics courtesy Lew Harriman/ASHRAE