Glossary of Sound Terminology

Cycles per second (CPS): In acoustics, the cycle is the complete oscillation of pressure above and below the atmospheric static pressure; CPS refers to the number of sine-wave oscillations that occur in one second. Low-frequency sounds have fewer and longer oscillations. Also expressed as hertz (Hz).

Decibel (dB): Sound — or noise — is a mechanical wave that oscillates through a medium; when it passes through air, it’s measured in decibels. As sound increases or decreases, decibels increase or decrease logarithmically, thus doubling the volume of a sound shows only a 10-point increase in dB.

dB(A): The most common measure of loudness, obtained by applying an A-weighted frequency response curve to the sound (as measured by a sound-level meter) to simulate what the human ear hears.

dB(Z): A sound-level meter reading with no weighted filtering.

Frequency: The number of times per second that the sine wave of a sound repeats itself.

Noise reduction (NR): The difference in sound-pressure levels between the inside and outside of an enclosure.

Noise-reduction coefficient (NRC): A measure of the acoustical absorption performance of a material, calculated by averaging its sound-absorption coefficients at 250, 500, 1,000, and 2,000 Hz, expressed to the nearest multiple of 0.05. NRC values range from near 0.00 for hard materials like glass to 1.2 for absorptive materials like fiberglass.

Octave: A pitch interval of 2 to 1, so that the upper tone has twice the frequency of the lower tone.

Octave Bands: Sounds that contain energy over a wide range of frequencies are divided into octave bands. The center frequencies for the 10 most common bands are usually 31.5, 63, 125, 250, 500, 1,000, 2,000, 4,000, 8,000, and 16,000 Hz.

Sound pressure level (SPL): An expression of loudness or volume at a given distance from the source, in decibels (dB). A 10 dB increase in SPL represents a doubling in volume.

Sound transmission class (STC): A rating for doors, windows, enclosures, noise barriers, partitions and other acoustical products that indicates their relative ability to block frequencies in the 500 Hz to 2,000 Hz range, where speech occurs.

Transmission loss (TL): The reduction in sound level when sound passes through an assembly.

Locating the Units

In new construction, it’s obviously best to plan the installation so that the mechanical unit is as far as possible from neighboring windows. A certain amount of noise reduction can be expected when sound travels from the unit to the nearest bedroom window (if we are worried about the owner of the outdoor unit), or the nearest boundary line (if we are worried about the neighbor or code compliance). But other variables need to be taken into account as well: Topography, ground cover, nearby structures, and even atmospheric conditions can bend the acoustic wave up or down, making it louder or quieter.

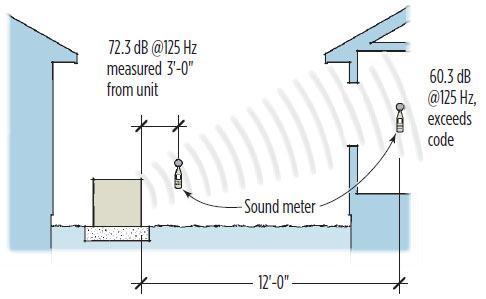

There are various formulas for calculating the net result of these ground and scattering effects, but for a quick estimate you can use what is called the inverse square law, which says that there is a 6 dB decrease of sound pressure level (SPL) per doubling of the distance. If the manufacturer’s SPL was recorded 3 feet away from the unit, moving 6 feet away from the unit would yield a 6 dB reduction; for an additional 6 dB reduction, you’d have to move 12 feet away.

Calculating Noise Reduction Based on Barrier Heights

Noise levels (measured in dB) vary depending on the source’s sound power level, site conditions, and the distance between the source and the receiver. In order to be considered a nuisance or noise code violation, noise levels must exceed a specified amount at a given location, typically 3 feet inside the nearest window, as shown in (A). Placing a high-STC barrier, such as a plywood-sheathed wall lined with an acoustic blanket, between an AC condenser or other source and the receiver will provide additional noise reduction, as shown in (B) and (C). To predict whether noise reduction levels from barriers of different heights will provide sufficient noise reduction levels at specific frequencies, the author uses the chart below. Because decibels are a logarithmic measurement, even a modest 10 dB decrease represents a 90 percent change in sound energy — which the ear will perceive as being half as loud as the original noise (see table at bottom).

Existing Installations

When an existing installation is causing a noise problem, I start by identifying the frequency and decibel level of the noise coming from the mechanical unit. We usually measure these levels with a sound meter, but you can sometimes get good acoustic data from the manufacturer. “Sound ratings” that don’t specify the weighting of the reading or the distance that the reading was taken from the unit (requirements of most noise codes) aren’t very useful. What we prefer to see are octave band levels that indicate which frequencies have the highest decibel ratings, detailed with information about weighting and distance, rather than a vague single-digit rating number. If I’m using information from the manufacturer, I keep in mind that its figures are only estimates and that on-site noise levels often are higher.

I also refer to the manufacturers’ specifications when I’m trying to determine the correct treatment for structure-borne noise, to find out the weight of the unit and the rpm of the motor. If there’s a local noise ordinance, it will usually specify the acceptable noise level for different sources of sound. In New York City, the noise-level limit for a single AC unit is 42 dB(A) as measured from 3 feet inside the nearest open window. But most noise ordinances also require that noise levels don’t exceed ambient — or background — noise levels by more than a certain amount when the unit is turned on. So I use a sound meter to estimate ambient levels and refer to them when setting noise-reduction goals.

For example, if the SPL of a condenser is 73 dB(A), and the acceptable noise level is 42 dB(A), the theoretical target noise-reduction level would be 31 dB. Code officials in New York currently enforce a limit of 3 to 4 dB over ambient levels, which often can measure as much as 48 dB(A) in the city. That means that the acceptable noise level for the unit may actually be as high as 52 dB(A), and the target noise-reduction level would be 21 dB.

Cost

Costs for building soundproofing enclosures can vary widely depending on site conditions and noise-reduction goals. For instance, the materials to build a two-sided enclosure for the pre-existing AC condenser shown the slideshow cost only $1,300. We didn’t have to satisfy any noise codes, just a nearby neighbor, and the enclosure height was limited to 5 feet to avoid blocking the view out of the windows.

The cost to design and build the 10-foot-tall soundproofing barrier for the standby generator in the slideshow was about $15,000, including materials and installation. This barrier had to block enough noise for the generator to comply with local noise ordinances, yet not exceed zoning height restrictions.

Bonnie Schnitta is the owner of SoundSense, an acoustic consulting firm and manufacturer of sound-control products.