The 26th annual JLC Live conference and expo opened with bang on March 23, 2023, with a record attendence of more than 8100 attendees. As always, the expo was set alight by the Building Clinics, featuring Mike Guertin (at right in photo above), Peter Heard, Mike Sloggart, Tom Brewer, Mike Kennedy, Ben Bogie, Myron Ferguson, Rick Arnold, Jon Namba, Tony Blue and the three winners of the “Next Presenter” contest: Aron Jones, Aaron Miiller, and Sam Durdaler, all of whom continued the tradition of making JLC articles come to life – a.k.a. putting the “live” in JLC Live.

The exhibitors also came in full force and didn’t disappoint. Here are a number of the new tools and products that caught our attention:

A Powerful Cordless Coring Drill With Patented Safety Features

The MX Fuel Handheld Core Drill (left) with its larger, longer-lasting XC lithium-ion battery pack removed (middle). Milwaukee Tools' Christopher Losch attaches a Diamond Ultra Wet Core Bit to the core drill mounted to the stand (right).

Christopher Losch of Milwaukee Tool demonstrated its MX Fuel Handheld Core Drill for JLC at the show. Able to core holes up to 6 inches in diameter in reinforced concrete, according to Losch, Milwaukee’s MX Core Drill can be powered by either its XC lithium-ion battery pack (reportedly capable of fully charging in 90 minutes) or its more compact CP battery pack (fully charging in as few as 45 minutes). Losch added, “If you’re coring 3- to 6-inch-diameter holes, you’d probably want to use it in tandem with our Compact Core Drill Stand for added drilling confidence. For holes 3 inches or less, you can usually core concrete or block while holding.”

Run times vary depending on the diameter of the hole and the material being cored into. For example, with the CP battery, you can core nine 3-inch holes in concrete block or five 3-inch holes in 6-inch-thick concrete; with the XC battery, 18 3-inch holes in concrete block. Regarding safety, Losch said, “The MX is the safest handheld core rig available. It has our patented Autostop technology, which cuts the drill off automatically when you feel it torqueing. This is particularly important if you happen to be working above your head or on a ladder.” The drill can be run wet or dry. For coring concrete dry, the manufacturer recommends using its Dry Coring Dust Extraction Attachment, which allows you to be OSHA compliant when drilling. Milwaukee plans to release a new drill capable of coring 14-inch-diameter holes in concrete in later this fall (2023).

Rethinking Deck Joists, Hangers, and Wood Screws

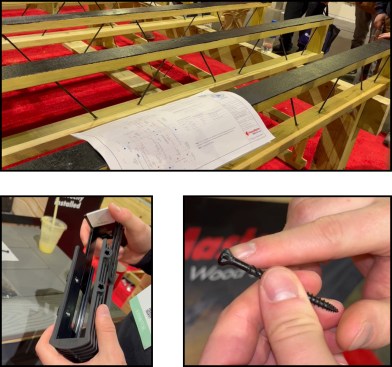

FastenMaster’s Icon Screw Joist System (top), EVO Joist-to-Ledger Deck Framing Connectors (bottom left), and MVP Multipurpose Wood Screws (bottom right).

Shaun Jennings of FastenMaster reviewed three new product lines with JLC: its Icon Screw Joist system, Evo Joist-to-Ledger Connectors, and FastenMaster MVP multipurpose wood screws.

Icon Screw Joist System. In development since 2013, FastenMaster’s Icon Screw Joist system debuted at this year’s JLC Live Show. The joist’s new look is typified by its diagonal double-threaded screw web members and 3-1/2-inch-wide top and bottom chords. According to Jennings, “Screw Joists are lighter in weight than traditional joists, dead flat, faster to install, and come pre-coated with asphalt waterproof coating—so, no more taping the tops of the joists is needed.” A builder simply sends the needed deck dimensions to FastenMaster, and it does the rest: the engineering, stamped design drawings, manufacturing of the components (including carrying beams and posts), and delivery to the jobsite 100% ready to go. For the initial rollout, the joist system will be available only in Massachusetts, Rhode Island, and Connecticut (check with the manufacturer regarding availability in other areas).

Evo Joist-to-Ledger Deck Framing Connectors. According to FastenMaster, its new, high-grade-polymer-based joist hangers offer a “no-rust, no-corrosion” alternative to traditional galvanized metal hangers. The Evo Connector is adjustable to accommodate 2×8 or 2×10 joists, and its top piece acts as a lip to hold the joist temporarily in place while being fastened. Shaun Jennings said, “To install, first clinch the Evo Connector to the joist, drive the set screws (one on either side of the hanger), place the joist in position, then drive home the four 5-inch-long heavy-duty screws.” The joist-to-ledger connectors come in 16-piece project packs or in individual packs, with screws and hex driver bits included. Available for sale now, they will hit lumberyards across the country in the next two to three months.

FastenMaster MVP Multipurpose Wood Screws. Long known for their large screws, FastenMaster makes its first foray into the smaller, multipurpose, interior-exterior screw market with its new MVP line. According to Jennings, “MVP fasteners have the same coating as other FastenMaster products. Our Torx ttap screw head is designed to be that second hand and prevent wobbling while driving; there are no magnets holding the screw to the bit.” Available in 1 1/2- to 4-inch lengths and in packs of 100 up to 2,000, the screws will be available in lumberyards within weeks.

Natural Wood Made to Last

The Click-in Cladding System (left), a New Zealand radiata pine sample (right). The dual-modified wood was chemically and thermally treated at Kebony’s Norway manufacturing facility.

Jim Dowd of Norway-based Kebony talked to JLC about its dual-modified wood product used for decks, docks, boardwalks, and cladding. According to Dowd, “We’re the only dual modified wood on the market. We both chemically and thermally treat the wood, which polymerizes it, adding 50% more density to the parent wood. The finished product is largely hydrophobic. So, when it’s delivered to the jobsite it’s going to have a moisture content of around 4% to 6%. While in service outdoors as siding or decking, its moisture content will rise to only about 8%.”

Kebony’s 5/4x 6 Deck Board comes in lengths up to 16 feet long and can be face-fastened, countersunk and plugged, or attached with their hidden fasteners. Their click-in cladding is secured with extruded aluminum rails and plastic clips which are pre-spaced out to provide various gap designs, such as nickle gap and ship-lap gap. The rails are fastened using a ring-shank stainless steel gun nail at 16- or 24-inch on-center spacing. All Kebony woods have a deep brown color that ages to a silver-gray color over time.

A Thermal Envelope System That Allows for Drying

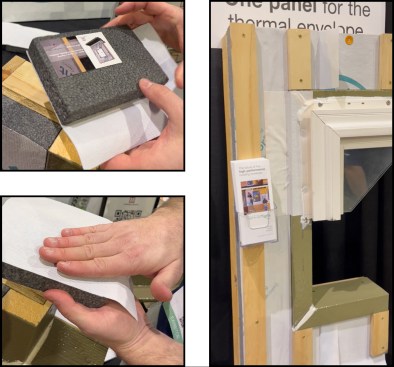

ThermalTight’s Neopor GPS semi-vapor permeable foam insulation (3.5 perms). The foam is a graphite polystyrene made without harmful blowing agents (top left). Its vapor permeable WRB (42 perms) is laminated exterior face of the foam panel (bottom left). The ThermalTight system is designed to work in concert with ThermalBuck high-performance window bucks (right).

Max Taylor, president of Thermal Building Supply, discussed the ThermalTight System with JLC. According to Taylor, “ThermalTight combines two building envelope materials into one, easy-to-install panel; a semi-vapor permeable Neopor GPS rigid insulation and a vapor permeable WRB laminated to the exterior face of the foam panel, that acts as both a water and air barrier. Taylor added, “The non-woven, non-perforated polypropylene WRB is extended beyond the edges of the rigid panel 2 inches on all four sides. The resulting flaps are used to seal the panels together, allowing the WRB to function not only as a water barrier, but as a continuous air barrier too.” All seams are sealed with the manufacturer’s double sided tape.

ThermalTight Panels are available in three different thicknesses—1-1/16″ (R5), 1-1/2″ (R7), and 2-1/8″ (R10)—and three different size panels—4′ x 8′, 4′ x 9′, and 4′ x 10′.

A Pair of Precision Tools

Two tools stood out for us at the Festool booth: a new cordless table saw (which isn’t available quite yet but reportedly will be soon) and a full-size cordelss recip saw.

The new CSC SYS 50 cordless table saw is as compact as a table saw can be, weighing in at only 33 pounds. It’s designed to fit in its own Sys container (larger than the typical Sys container). Festool says this tool is geared for finish carpenters, and perhaps if the carpenter is using a track saw to dice up sheet goods, it will suffice. The maximum width from blade to fence is only a smidge over 11 inches (280mm); the maximum crosscut using the built-in sliding table is 17.7 inches (450mm). The sliding table also includes a well-designed angled fence for cross cuts that adjusts from -70 to 70 degrees.

The depth of cut with the blade vertical is a maximum of 1.89 inches (48 mm), and 1.3 inches (34 mm) at 45 degrees. Blade height is adjusted digitally using tiny servo motors to move the blade up and down (reportedly accurate to within 0.1mm). The blade height is punched in using a dial and digital display. While this may take a bit of a learning curve, this systems allows you to preset four different heights. This could be great for cutting rabbets, T&G and other joinery that may require different-depth cuts on the same piece of wood.

In typical Festool fashion, the entire piece of equipment exudes precision and refinement, and is well designed to limit dust when hooked up to a dust extractor (which can be operated using the Bluetooth battery system). However, as precision a tool as it may be, it’s tiny; the limited rip capacity is especially disappointing. For an expected price tag of $1,700 to $2,000, it’s especially hard not to feel a little dismayed that this tiny wonder does not include the SawStop blade braking system (Festool acquired SawStop in 2017).

The cordless Festool RSC18 comes with a number of useful features, including an adapter that allows you to position the end of a vacuum hose near the blade, a ladder hook, and a quick-disconnect collar that ejects the blade .

Festool RSC 18 cordless reciprocating saw. On a much more exciting note, in our opinion, the RSC 18 cordless recip saw seems to be an especially nice version of this tool of all trades. Though we haven’t put it through it’s paces, the tool in the Festool booth exuded power on a well-charged battery. Like many powerful reciprocating saws, it includes an adjustable power stoke (Festool calls it the “pendulum stroke,” similar to Bosch’s orbital, or elliptical, action) that kicks the blade back and forth as it saws up and down, helping to clear the kerf of dust and speed the cutting action. Yet with all this power, what’s happily missing is vibration; it’s not hard to imagine this would result in much less fatigue through long and grueling cuts.

A few exceptional features on the the RSC 18 make this a standout tool in the field of cordless recip saws: Chief among these is mounting system that allows you to position the end of a vacuum hose on the shoe to collect dust coming off the blade.

This recip saw also comes with a ladder hook, and the blade collar seems especially well thought out for quick blade changes. The blade can be ejected by simply rotating the collar so there’s no danger of burning your fingers when removing a saw blade. The clamped blade can also be rotated by 180 degrees, so you don’t have to take it out and reinstall it when you need to cut in the opposite direction.

Cable Rail “Infill Panels” Right Out of the Box

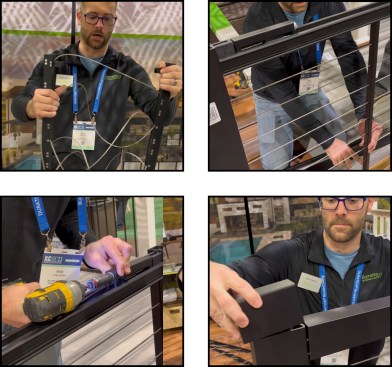

The cable guide assembly comes out of the box with pre-strung (top left). After attaching Elevation Rail’s aluminum posts to the deck, the cable guide assembly is slid into the extruded posts from the top and then the subrail is cut to length and installed between the two posts. The tensioners are placed at each post location, and the line slack is pulled out by hand at each tensioner (the tensioner has a locking mechanism that prevent the cable from backing out). The center support piece is installed (top right), then the cable rail is screwed taught with an impact driver at each tensioner—one tensioner is pulling cable from the top and the other one is pulling cable from the bottom (bottom left). The top rail cover is cut to length and snapped over the subrail, then the end caps are press-fit tightly into the posts (bottom right).

Say goodbye to specialty tools and fasteners needed for installing cable rail on decks. Andy Vachon of Barrette Outdoor Living demonstrated RDI Elevation Rail for JLC at their booth. According to Vachon, “RDI’s pre-strung infill panels can expand up to a maximum of 6-feet between posts and can be installed on both decks and stairs. The rails, posts, and caps are cast aluminum while the continuous cable rail is 316 stainless steel. Vachon added, “No specialty tools are needed, except maybe a good set of cable cutters to prevent fraying the cable. Because of our cable tensioner, our cable rail shouldn’t grow slack over time as much as other systems. But, if they were grow slack, you can pull the top rail cover off and tighten the stainless-steel cables back up with an impact driver.”

Composite Shake Panels with a Realistic Finish

Alex Catron (right) demonstrates the Beach House Shake panel’s realistic finish and texture (left).

Alex Catron and Jim Carlson of Tando reviewed the manufacturer’s Beach House Shake panels with JLC. Tando’s composite shake panels are made from polypropylene resins and earthen minerals (the minerals help reduce expansion and contraction and improve UV stabilization). According to Carlson, “The improved UV stabilization allows us to offer a 20-year no-fade warranty. Over that time, our Beach House Shakes are guaranteed to look as new as the day they were put up.” While Catron notes, “Each box holds 11 panels with random shake layout patterns and finishes. Our finishing process creates a noticeably random, unique stained finish on each panel, resulting in the installer not having to worry about piecing the product together to achieve a nice blended wall.”

Regarding installation speed and fastening, Carton notes, “Our panelized shakes can be installed 5-times faster than natural cedar shingles and with less fasteners. Natural cedar shingles usually need 3 to 5 fasteners per shingle—5-square feet of cedar shingles usually require at least 42 fasteners. The same coverage of our Beach House Shake only require 7 fasteners. So, there are big savings on labor and fasteners.”