To test a line laser for accuracy, begin by projecting and marking level lines from two different locations that are as far apart as possible and checking that the lines are exactly parallel from end to end.

To test a laser for level, I use a time-tested method of checking the accuracy of any leveling instrument. In this example, I began by setting the laser – a DeWalt DCLE34030G 20V Max 3 x 360 line laser – on a side table in my living room. I marked at the laser line a few feet away on the front wall of my house, then I walked down the hall and through the door to my bedroom and marked at the laser line on the back wall of my house, which is 56 feet from the front wall. Then, I switched the location of the laser to the top of a dresser in my bedroom, which is a few feet away from the back wall. When I switched the laser on, the horizontal line was exactly 7/8 inch above the marks on the walls in both the living room and the bedroom, indicating that the level planes were exactly parallel and right on the money over 50 feet. This test exceeded DeWalt’s specification for accuracy for this particular laser, which is 1/8 inch over 30 feet.

Next, suspend a plumb bob and see if the laser's vertical line is aligned exactly with the string line.

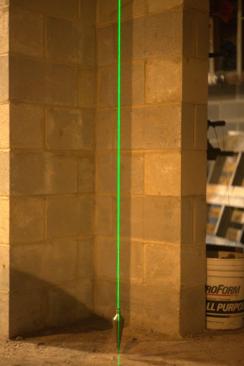

To test for plumb, I set up a 32-ounce brass plumb bob in my basement and waited until it was completely still. In this position, the string holding the plumb bob was, as they say, dead plumb. I set the laser on a short wall about 8 feet away and rotated the instrument until the vertical laser plane hit the string of the plumb bob. The string line lit up like a green neon sign from top to bottom, indicating that the plane projected by the laser was perfectly plumb.

To test that the laser lines are perpendicular to each other, measure the diagonals between two equal sides, remembering that the hypotenuse of an isosceles right triangle is always 1.4142 x the length of one of the sides.

To check for square, remember that the hypotenuse of an isosceles right triangle—a right triangle with two equal sides—is always 1.4142 times the length of the sides. To check the intersecting lines on the floor for true perpendicularity, I simply measured and marked 100 inches out from the point of intersection on each line. Then I multiplied 1.4142 by 100 in my head by moving the decimal point over two places. The result, of course, was 141.42. I converted the .42 decimal to 7/16 (again, in my head). Then, I measured that amount, 141 7/16 inches, diagonally from mark to mark to see if the laser lines were perpendicular to each other. This measurement was, indeed, 141 7/16 inches, proving that the two vertical laser lines were perfectly square to one another.

The same method can be used to test a laser level for square on a wall, though the size of the isosceles right triangle will by necessity be smaller than the one used to test for square on a floor.

To check the intersecting lines on the walls, I didn’t have the same luxury of space as on the floor. I had to use a smaller triangle to measure for perpendicularity, so I decided on 100 cm sides. After measuring and marking out 100 cm from the point of intersection on both lines, I measured across from point to point. Finding that distance to be 141.4 cm, I knew the laser lines of the DeWalt once again agreed with the geometry of Pythagoras.

Photos by Matthew Navey.