If you know your soil bearing capacity, following these practica…

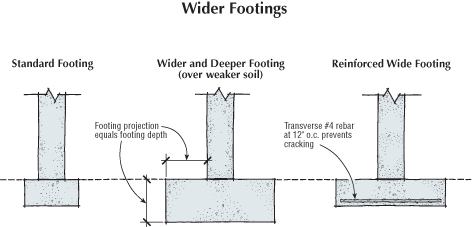

These numbers come from assumptions about the weights of building materials and the live and dead loads on roofs and floors. The allowable bearing capacity of the soil under the footing has to equal the load imposed by the structure. Reading down the table, you see that the code calls for a 12-inch-wide footing under a two-story wood-frame house in 2,500-psf-bearing soil. A 12-inch footing is 1 square foot of area per lineal foot, so the code is saying that the portion of a two-story wood house that bears on the outside walls weighs about 2,500 pounds — maybe a little conservative, but reasonable. The same size footing is called for under a one-story house if it has brick veneer — the brick is assumed to weigh as much as a whole second story.

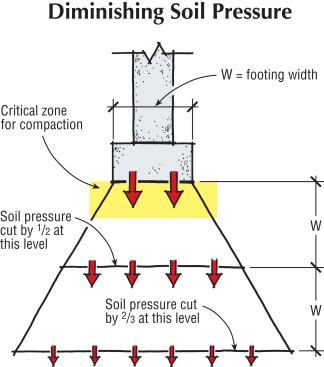

If you had an engineer design the footing based on soil testing numbers and your prints, he’d add up the actual weights of the concrete, wood, and brick you’d be using in your building, factor in the required live loads, and come up with an estimate of the weight your actual house puts on the footing. It might be a little less or a little more than the code assumes. Then he would take the known bearing strength of the soil — what a square foot of the soil can be trusted to support — and design the footing so that the area under the footing multiplied by the bearing strength of the soil would equal or exceed the actual load.

In practice, you don’t have to do this engineering on most houses. The amount you’d differ from a standard code-compliant footing isn’t worth worrying about. Unless you have retaining walls or some other special situation, an engineer’s fee probably isn’t justified.

In any case, I wouldn’t recommend that builders cut back on their standard footing size even if they know they’re building on strong soil. Regardless of bearing requirements, masons and poured-wall contractors want footings for their block or their forms to sit on. But the lesson to take is that when soils are very strong, (4,000-psf capacity or better), the footings may not be strictly necessary from the standpoint of bearing. This means it is less important, for example, whether the wall is correctly placed in the center of the footing.

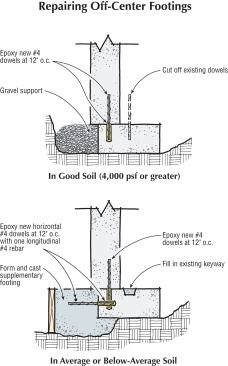

Fixes for Misplaced Footings

It’s hard sometimes to position footings in the trench, so contractors often see walls that are not in the center of the footing. The foundation wall has to be located correctly to support the house, of course, so it has been placed off-center on the footing.

In good bearing soil, I wouldn’t get too concerned about this foundation for the loads involved in a simple wood frame house. The full width of the footing isn’t needed to support the loads anyway; you could pour the wall right on the edge of the footing and still have enough support. However, if you start to go over the edge and have the wall sticking out past the footing on the side or on the end, then you’re starting to apply a rotational force that the footing is not designed to handle. In that case, you should think about getting an engineer involved. (If your soils are relatively soft, the risk is even greater.)

As an engineer, I’ve been asked to recommend solutions in cases where the footing has been placed so that the wall, when cast, would actually extend beyond it. My suggestions are different in strong soils than in average or below-average soils. In soils with bearing capacity greater than about 4,000 psf, I suggest excavating next to the footing and under it, and placing compacted large gravel into the space. That should be adequate to support the wall. If there’s a keyway in the wall, fill it in, and if there’s steel projecting from the footing, cut it off. Drill holes and epoxy steel into the footing to tie the wall to the footing, and then form and cast the wall. In weaker soils, you have to augment the footing itself with steel and concrete. Excavate as before, but instead of using gravel, drill into the side of the footing and epoxy steel dowels into it, then place concrete to extend the footing out to the proper width.

In weaker soils, you have to augment the footing itself with steel and concrete. Excavate as before, but instead of using gravel, drill into the side of the footing and epoxy steel dowels into it, then place concrete to extend the footing out to the proper width.