Spillage and Carbon Monoxide

The most dangerous effect of poor or negative draft is spillage, which is the entry of flue gas into the home. Flue gas can contain dangerous levels of carbon monoxide, which is odorless and poisonous. Carbon monoxide detectors are now required in many locations. It is a good practice to install one, whether or not it is required by your local code.

Methods of Venting

A boiler, furnace, or water heater can be vented either by atmospheric venting (also called natural draft or natural aspiration) or fan-assisted venting. In atmospheric venting, flue gases flow to the chimney — and ultimately to the outdoors — under their own power. Until the 1980s, almost all residential fuel-burning appliances used atmospheric venting.

Fan-assisted venting, also called induced draft or forced draft, can use either a sidewall vent or a chimney. A boiler or furnace that has been designed with narrow flueways (to increase efficiency) often requires fan-assisted venting to help suck the flue gas out of the appliance.

Sealed combustion.

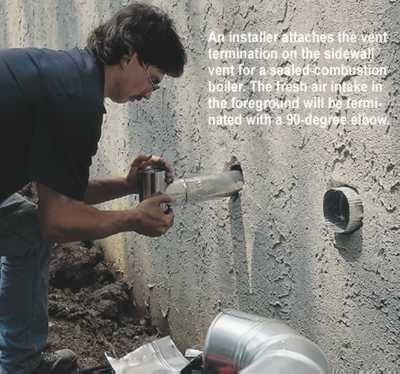

Sealed-combustion appliances draw combustion air from the exterior directly to the burner (Figure 2).

Figure 2. A galvanized pipe (foreground) provides combustion air directly from the exterior to the burner of this sealed-combustion boiler. A separate galvanized vent pipe conducts the flue gas through the sidewall. |

Because the fuel is burned in an environment that is entirely separated from the interior air of the living space, sealed-combustion appliances are unaffected by pressure differences inside the building envelope, and are therefore the best choice for tight houses. Some sealed-combustion appliances draw air in by means of concentric pipes, with the smaller diameter vent pipe located within the larger diameter air supply pipe. Sealed-combustion appliances can discharge flue gas either to a side wall, or up through the roof. Most sealed-combustion appliances use fan-assisted venting, except for some direct-vent space heaters.

Condensing vs. Non-Condensing Appliances

Fuel-burning appliances are categorized as either condensing or non-condensing. Non-condensing appliances are limited to about 87% efficiency. Condensing appliances are more efficient, because they extract more heat from the flue gas by cooling the gas to the point where moisture is condensed out. This condensation provides a latent heat exchange, boosting the efficiency of the appliance into the mid-90% range.

Because of the corrosive nature of the condensate, however, condensing appliances have different venting requirements from non-condensing appliances. The condensate can contain acid (sulfuric, nitric, or hydrochloric) that can corrode masonry chimneys, as well as some types of stainless steel vent pipe.

The type of vent material that can be used depends upon whether the appliance is condensing or non-condensing, and whether the venting is natural draft or fan-assisted (see table below).

Selecting the Right Vent

Appliance Type | Vent pipe required |

Category 1 appliances | Natural draft vent | Non-condensing | Lined masonry chimney or Type “B” or “BW” vent for gas or Type “L” all-fuel vent for oil |

Category II appliances | Natural draft vent | Condensing | Type AL29-4C stainless steel |

Category III appliances | Fan-assisted vent | Non-condensing | Type AL29-4C stainless steel or Type “B” vent (for vertical venting only) |

Category IV appliances | Fan-assisted vent | Condensing | PVC or ABS vent pipe |

Direct-vent appliances | Fan-assisted vent | Condensing | PVC or ABS vent pipe |

Direct-vent appliances | Fan-assisted vent | Non-condensing | Type AL29-4C stainless steel |

Location of sidewall vents. When installing a sidewall vent, you must maintain certain minimum clearances from grade, as well as from openings, gas meters, and electric meters. These clearances differ, depending upon whether or not the appliance is a sealed-combustion appliance .