Floor Insulation

Brian Butler

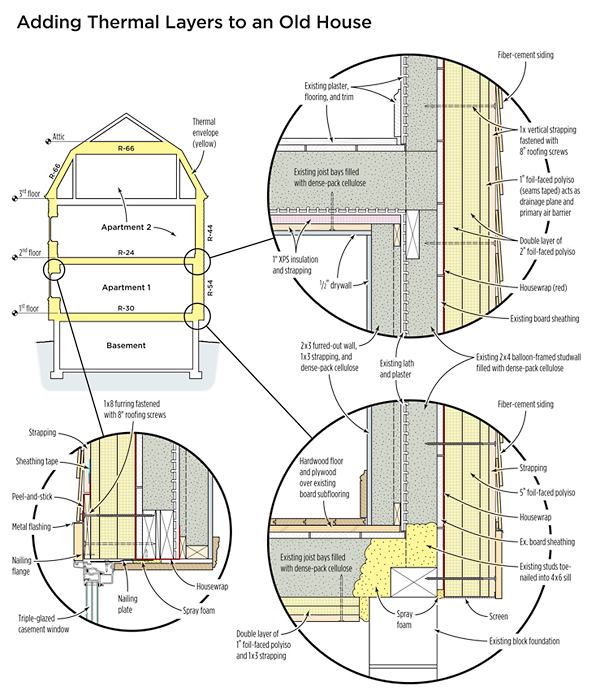

Given that the basement ceiling was too low to allow for living space, I decided to place the thermal envelope at the first-floor joists (except for a small centrally located utility closet). Insulating the basement ceiling was simplified by the fact that we were planning to replace all the existing wiring and plumbing anyway.

Because the house is balloon-framed, with its studs toenailed to a 4×6 sill, the first order of business was to spray closed-cell foam from a five-gallon kit against the exterior sheathing around the sill, filling the space where the studs and joist ends meet (but taking care not to let the foam expand beyond the bottoms of the joists themselves). Next, we fastened a layer of 1-inch foil-faced polyiso to the bottoms of the joists. We held the edges of the sheets an inch or so back from the sill, then filled the gap with more foam, which expanded enough to become continuous with the foam applied earlier. Later, after the enclosed bays were filled with dense-pack cellulose, we applied a second layer of rigid foam followed by strapping.

Interior Furring and Insulation

Although the shell was now well-insulated, we furred out the exterior walls of the downstairs unit to provide space for wiring and mechanicals and another 4 inches of cellulose. We first mudded over any cracks and abandoned receptacles in the original plaster, then nailed up three courses of horizontal strapping to each wall — one at the bottom, one at mid-height, and one just below the intersection with the ceiling. We then toenailed 2×3 studs to the strapping.

The stud cavity gave us room to install Lessco receptacle boxes. Like conventional airtight rough-in boxes, these include a wide flange that seals to the drywall with spray foam or caulk, but they’re easier to work with because there’s more room to get at the wires. After the insulation sub had netted and blown the cavities, we installed the drywall, sealing it to the electrical boxes with caulk.

To provide good thermal separation between the home’s two units, we also insulated the cavities of the walls around the two stairwells. And we added an inch of extruded polystyrene to the bottoms of the second-floor joists, then had the floor cavity dense-packed. This separation between the units will provide a useful “test lab” to the utility as it tracks energy usage, since the bottom unit is sealed and insulated to a higher level.

Mechanicals

A three-head ductless minisplit from Mitsubishi provides heat for the downstairs unit; the upper apartment is heated with an AO Smith water heater piped to a Unico fan-coil system. Each unit is also equipped with its own 90-percent-efficient Zehnder HRV. A grid-connected 7-kw photovoltaic array supplies the lower unit with electricity.

Summing Up

Post-project blower-door tests show that air infiltration in the upper unit has decreased from an initial 3,500 cfm at 50 pascals to about 1,800. As expected, the lower unit is much tighter, at just 350 cfm.

Still, that figure was higher than our original downstairs goal of 187 cfm (a target that would have allowed us to hit a Passive House standard for old buildings). On investigation, we found that a good deal of that leakage was coming in around the electrical boxes, which apparently weren’t caulked well enough when the drywall was hung. In hindsight I wish I’d supervised a little more closely, because it can be tough to get subs to fully grasp the importance of air-sealing.

We have our own blower door, so we’ve been able to track down most of the leaks with a smoke pencil and seal them with caulk or canned foam. In the case of the outlets, this involves removing the cover plates and injecting canned foam around the perimeter of the boxes through a straw inserted in the gap between the wallboard and the rough-in box, taking care to keep the foam out of the electrical boxes themselves. The master bedroom hasn’t yet been tiled and finished, so there’s still some low-hanging fruit available that should help us close the remaining gap.

The total project cost — before incentives — was $275,000. About $60,000 of this was directly attributable to energy improvements over and above code requirements. The utility pilot incentive totaled $54,000.

Brian Butler owns Boston Green Building in Allston, Mass.