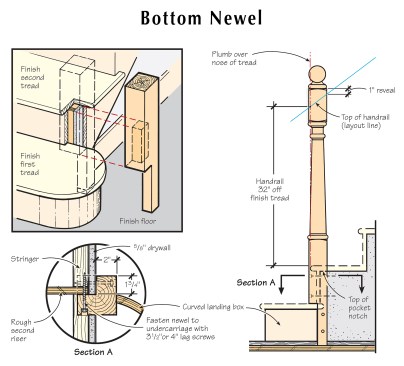

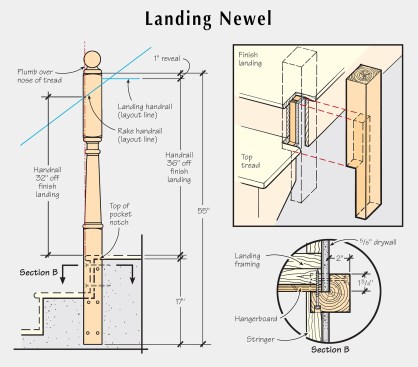

When post-to-post newels are turned on the lathe, blocks are left at the bottom for attaching the newel to the carriage and at the top where the handrails attach. Rails are typically attached to newel posts one inch below the edge of the top blocks.

Link to “Trimming Out Stairs” article

Editor’s note: This story is an accompanying piece to Jed Dixon’s March 1999 “Trimming Out Stairs” article.

Newel lengths. To determine the length of a bottom newel, you have to carry the line of the top of the handrail across to the front side of the newel to a point exactly over the nose of the second tread (slightly in from the newel edge, to allow the nosing to die into the newel with a slight reveal). This requires knowing the angle or pitch of the staircase. Although you can estimate the angle with a sliding T-bevel, I like to use a calculator for added precision. The angle equals the inverse tangent of the rise/run. On a scientific calculator enter Rise ÷ Run = Inv Tan. Or with a Construction Master calculator, enter the rise per tread and the run per tread and push Pitch. With a rise of 7.5 and a run of 10, it’s 36.9 degrees.

Bottom newel. From this point, measure down 32 inches to where the level of the finish tread nose will be. Because the finish tread slides under the bottom newel, this line becomes the top of the pocket notch. To create as strong a connection as possible, I extend the bottom newel all the way down to the subfloor so that the flooring sub can lock the post in place with his flooring. If I don’t beat the flooring sub to the job, I’ve got to give up on this detail and scribe it to the finish floor.

Landing newel. The landing newel is a little bit different — it has a longer top block that allows it to pick up both the landing rail at a height of 36 inches and the rake rail at 32. Leaving a 1-inch reveal above the landing rail, the top edge of the newel block has to be 37 inches over the finish floor. The bottom end of the landing newel should extend below the face skirt board. Typically, you also have an apron on the landing. If the stair turns and rises up the next run, the next face skirt will also butt into the landing newel. In either case, it’s common to run base cap upside-down on the apron, or under the face skirts, and your newel has to be long enough to catch every-thing. I always draw it out full-size (either on the wall or on paper) to determine what that length is. Typically it’s around 17 inches if you use a 1×10 for your skirt board.

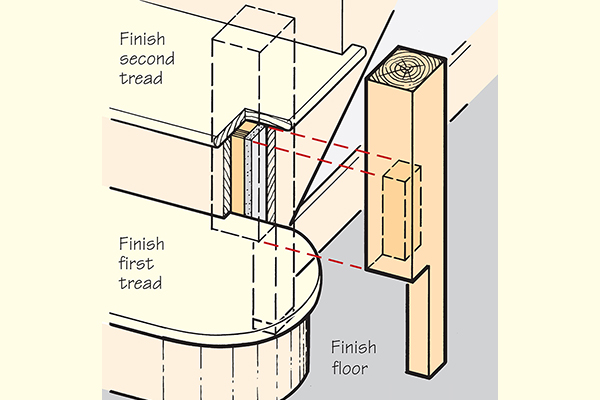

Pocket notches. Newel pocket notches need to position a newel front to back so that the tread or landing overhang dies into the newel, and side to side so that the newel is centered on the handrail/balustrade centerline. Front to back, we know that there’s a 1-1/8-inch overhang plus a 3/4-inch riser plus a 1/8-inch reveal. That’s 2 inches, which brings us to where the bottom portion of the cut is made. Side-to-side in our example (with 1-1/4-inch balusters, 5/8-inch drywall, 1 x 10-inch skirt board, 1/8-inch reveal), the side of the notch cut ends up being 1/8-inch beyond the center of the newel.

Beyond this, layout differs for bottom and top newels. For the bottom newel, the lower section must be cut to fit around the curved riser box used for the first step. In addition, the pocket needs to make way for the tread to slide underneath. And over the tread, the notch positions the newel front to back so that it catches the overhang of the next tread up. For a landing newel, the pocket positions the newel from front to back in the same manner. On the lower portion of the cut, however, the newel runs full width.

Illustrations by Tim Healey