Environmental Health Watch

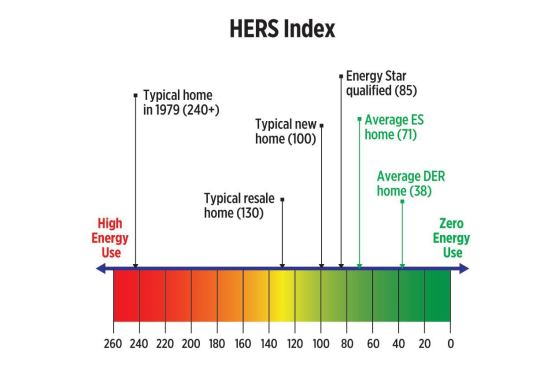

All of the houses in the HUD-sponsored technical study were buil…

Hvac Systems

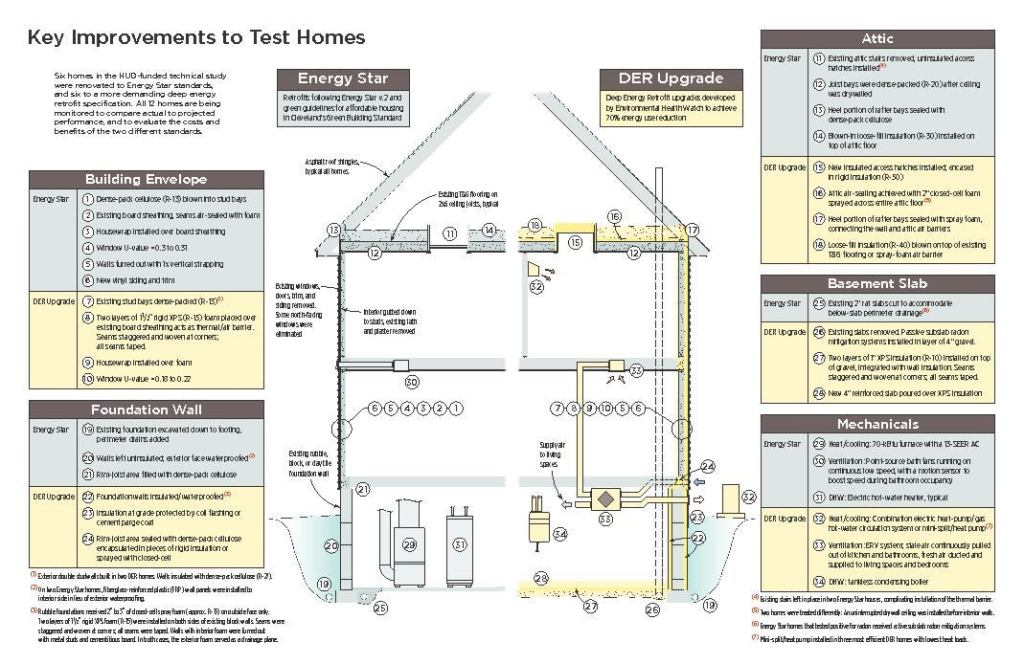

The six Energy Star houses were supplied with typical exhaust-only ventilation, using point-source bath fans to meet the ASHRAE 62.2-1989 ventilation standard. These fans run continuously on low speed and have a motion sensor to boost speed when the bathroom is occupied. In the six DER houses, a balanced energy recovery ventilation (ERV) system was used instead of exhaust-only ventilation.

Heating and cooling. We used three different hvac systems in the 12 retrofitted houses. The standard system in the six Energy Star houses was a natural-gas power-vented 71,000-Btu/hr furnace with 13-SEER AC. The peak heating loads were projected to average 41,000 Btu/hr in the Energy Star houses.

In the DER houses, projected peak heating loads were reduced by 69% on average to 12,700 Btu/hour. This amounted to a 91% reduction in the annual heating requirement (MMBtu), so we were looking for much smaller capacity systems.

For the first three DER houses, we used fully ducted electric heat-pump and gas-powered hot-water combination systems. These systems use traditional ductwork, with an air handler tied to a heat and AC coil instead of a furnace. Their primary source of energy comes from the electric heat pump. For backup heat (and when this option is more efficient than the outside heat pump), water heated by a Navian 98% efficient condensing tankless hot- water heater circulates through the heat coil/air handler.

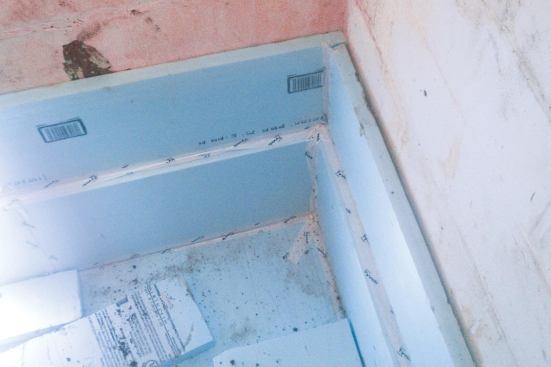

For the last three DER houses (those with double studwalls and the lowest heat loads) we used wall-mounted ductless mini-split air-source heat pumps. This setup relies on point-source heating and cooling, along with minimal heat loss and internal circulation fans for distribution and circulation (see photo, page 63).

Lessons Learned

The experience of installing these different hvac systems taught us some things about what does and doesn’t work for energy-efficient affordable housing. The assumption going into the job was that reducing the heat load by 69% would result in cost savings for the mechanicals, and that smaller hvac systems would help pay for the super insulation and other upgrades. In reality, we ended up paying a few thousand more for the smaller-load systems.

The hvac systems presented a number of challenges. Standard systems are clearly easier, despite the fact that they are all too large for the loads that we were trying to manage. You can get pretty good efficiency out of a new furnace at a very low cost, so there is not much room for savings with alternative systems. They don’t yet make furnaces small enough to be right-sized for super-efficient homes, so we were forced to either make the house less efficient or try out options beyond the typical furnace.

Occupant learning curve. Despite our confidence in the heat-load and system-capacity projections, there was great concern for how the mini-split systems would work out for the average occupant. On paper, they are sufficient to keep the house comfortable, but most people are used to large, oversized furnaces that can blast the house to 80°F in a short time. But mini-split systems work differently. They are sized closer to the projected load of the home, and therefore the system may struggle to keep up with occupant expectations. We provided education about the heating systems, but the families were not necessarily interested in changing their habits just for the sake of this study. Mastering the programmable thermostat was also a challenge for some of the residents, though in many cases, it was device failures that created the problem (the thermostats would not hold the correct time, and they messed up the heat schedule so badly people gave up on programming them).

Also, ongoing maintenance costs of the mini-splits were a concern for CHN, the developer. CHN believes that ongoing maintenance costs will be higher overall, due to the limited number of experienced installers for the newer systems.

Contractor learning curve. The most cost-efficient and energy-efficient option might not be the best option — at least not yet. A typical furnace is robust and can run for years with a dirty filter. It is powerful and oversized, so it reacts quickly to extreme conditions. It is cheap and available, and it is fairly simple for any hvac contractor to install, repair, or replace.

By contrast, the mini-split/ERV system — which is the most efficient and should be one of the most affordable options, considering the simple install and reduced duct work — presented the most problems. Few local hvac contractors and suppliers had experience with this product, and the challenge of getting these systems designed and running properly on the first attempt was more expensive than we expected, reducing our projected savings.

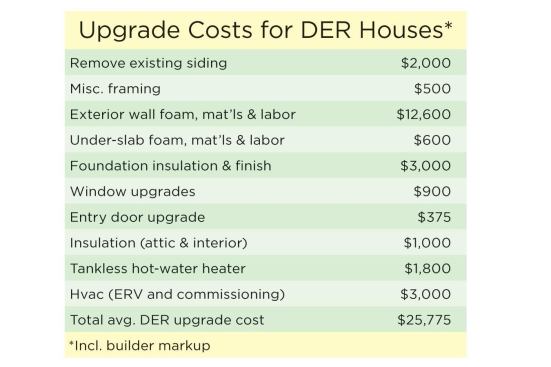

Overall, the hvac upgrade cost on the DER homes (mini-split/ERV system) was roughly $3,000 more than the base system (furnace and exhaust-only bath fans). About two-thirds of this was the cost of the ERV, with the rest going to a consultant for basic commissioning (mainly balancing of exhaust and intake ventilation rates), a process with which the installers and developer were not familiar. (Commissioning — a formal quality-assurance process that ensures the equipment operates as designed — was not seen as part of the standard scope-of-work and was an upgrade, which many of the hvac contractors were unable to provide.)