Band clamps pick up where other clamps leave off on projects that require clamping of complex assemblies. Merle (pronounced “Merrill” not “Merr-lee”) band clamps easily handle anything from triangles to decagons and everything in between … they even work for clamping circles and ovals.

Sturdy, self-adjusting cast-aluminum corners are easily added or removed with finger pressure on pull-off clips to suit the task at hand. The infinitely adjustable steel band provides amazing pressure that’s equally distributed between corners, regardless of the number. Non-marring, high-impact ABS plastic pivoting jaw inserts conform to surfaces of any shape they’re in contact with. Turning the stout plastic tensioning handle applies pressure evenly to each joint in an assembly. When glue cures under this pressure, glued joints have maximum strength, making biscuits, splines, or interlocking joinery unnecessary in some joints. The clamps come with 23 feet of high-tensile steel band that allows clamping of frames from as small as 2 5/8 inches square all the way up to more than 5 1/2 feet square.

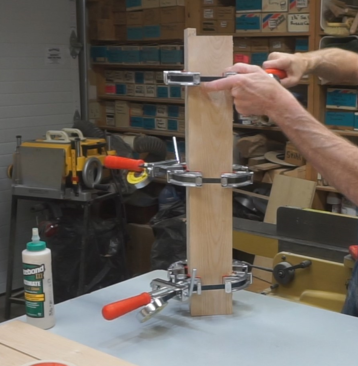

Common uses of band clamps include clamping picture frames, cabinet casework, drawer boxes, and chair legs. Beyond that, I find them invaluable for glue up of wooden “tubes,” like square box newel posts and hexagonal “blanks” for turning into wood cylinders or columns. It’s a good idea to dry fit and clamp a project together to make initial adjustments to clamp corners, get the steel strap within screw-tensioning range, and make sure joints fit properly before getting serious and applying glue.

Because of the unique design and operation of these clamps, they seemed a bit unwieldy at first, but I quickly realized that, compared with any other system, they’re very manageable in use.

I have only two nits to pick about the clamp design, but they’re nowhere near deal breakers:

One: I think some sort of cam-action lever for securing the band for rough length adjustment would be an improvement over the effective but awkward lever bolt used for the purpose. Ergonomics for tightening the lever bolt are less than ideal and the lever can end up at an annoying angle when tight.

Two: Having a way to keep the excess band confined is essential, but the compact wind-up metal “case” that stores the band can be startling in use when tension from the coiled steel band is released. I’m not sure what the solution is, but I mention it to alert unfamiliar users.

At about $30 for a single clamp or $135 for the Shop Master Set (which includes four band clamps plus eight extra corners), these band clamps will put a serious squeeze on glue joints but not on your tool budget.

Check out the clamps in action in the video below: