After several unforeseen delays on our Attainable Zero project, the insulated slab foundation is in and, framing is underway and soon the roof trusses will be set.

In This Series:

Attainable Zero: A JLC Case-Study Home

Attainable Zero: Building to ZERH Standards

Attainable Zero: Preconstruction Begins

Building in the Unknown: Pushing Forward with Attainable Zero

Attainable Zero: Permits and Preconstruction

Attainable Zero: In the Ground

Attainable Zero: Building the Bones of the House

As with every Addison Homes project, reaching the level of performance we expect is not always straightforward. One unexpected delay came during the foundation slab preparation inspection. As discussed in my previous post, we use recycled aggregate to fill the stem wall foundation prior to pouring the slab. This approach helps reduce embodied carbon and supports our broader sustainability goals. In this case, however, the local building inspector was unfamiliar with the code provisions governing recycled aggregate and initially told us it was not allowed. That uncertainty paused the project for a couple of weeks while we worked with the inspector and his supervisor to review the applicable code language.

Once everyone was aligned on the requirements, we were able to move forward using the recycled aggregate as planned.

Bringing the Framers Up to Speed

Once we finished the foundation, we were excited to get started on the framing. But again, this phase introduced several familiar challenges, namely bringing a new framing crew up to speed on how we build. While the framing contractor is one we regularly work with, the crew assigned to this house had not built for us before. They understood that Addison Homes builds to a higher standard, but our level of detail and expectation is not typical in the industry.

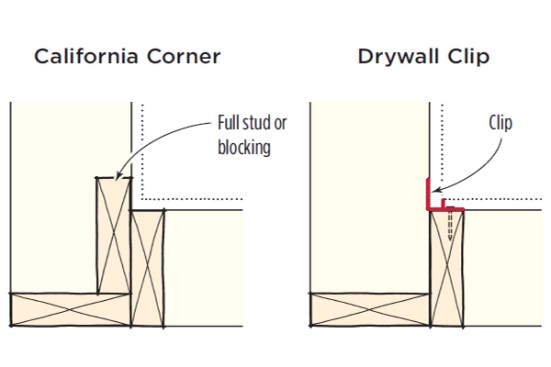

That difference showed up almost immediately in the framing details. One example was the use of a three stud California corner. Our standard is a two stud corner using drywall clips, which eliminates unnecessary wood and reduces thermal bridging. (For a comparison of the two methods, see he illustration below.) The cost difference of a single stud is minimal, but the performance impact is not. Fewer studs mean more room for insulation and better thermal performance at the corners, which are some of the most vulnerable areas in the building envelope.

These framing details matter because the Attainable Zero House is designed to meet very high performance goals. Like all Addison Homes projects, it will be certified as a DOE Zero Energy Ready Home.

Fortified Gold. In addition, this will be the first Fortified Gold home we have ever built. Fortified Gold is the highest level of the Fortified Home program and focuses on durability and resilience, particularly resistance to high wind and severe weather.

Building to the Fortified Gold standard places added importance on framing connections. In a light wood framed home, strength comes from how everything is tied together. The connections from the foundation to the bottom plate, from studs to top plates, and from walls to roof trusses must form a continuous load path. Standard nailing alone is not enough. Fortified requires additional straps, fasteners, and connectors to ensure that loads from wind or other forces are transferred safely all the way to the foundation.

Because this is our first Fortified Gold project, these requirements are new not only to this framing crew, but also to many of our trade partners. We provide a detailed construction manual that shows exactly how we want key assemblies built, from two stud corners to insulated headers and intersecting interior walls. This level of documentation is not typical on most jobs in our region, where crews are often told simply to frame the house the way they always do. On this project, we are much more hands on, reviewing construction details, answering questions, and correcting details as needed.

Once framing and Fortified connections are complete, the project will move quickly into the next phases. Continuous exterior insulation will be installed, wrapping the house to improve thermal performance and air control. From there, we will move into rough in work for plumbing, electrical, and HVAC.

Minor Changes

There have been only a few changes to the original plan since construction began. One was extending the roof over a side porch to provide better protection for large sliding doors and create a more usable covered outdoor space.

Another significant decision involved the roof assembly. We initially were evaluating exterior insulation on the roof deck, but challenges with Fortified connections and workflow resulted in excess costs, so we have been working with our spray foam contractor to put together an above code approach to sealing and insulating the roof deck to meet our performance and budget goals. After years of doing this, I’ve found the ability to adjust and change makes the whole project flow simpler, faster, and on budget – but only if you can see the changes well in advance.

As the bones of the house come together, this phase reinforces an important lesson. Small framing decisions add up to big differences in performance, durability, and resilience. Taking the time to get these details right builds the foundation for everything that follows. With framing well underway, we are well positioned to move into the next phase of construction and continue turning the Attainable Zero vision into a reality.